E-line heavy workovers in high latitude environments

- Temperature Below -50°C

- Undiscovered Approx. 22% global resources

Background

Drilling and producing in high latitude environments is unforgiving. Temperatures often drop below -20°C and can reach as low as -50°C. Isolated locations or vast distances, extreme weather conditions and periods of deep darkness can restrict transportation of personnel and equipment.

As a result, job complexity often leads to outright failure or an exponential increase in time to accomplish what would be a routine task in a normal environment. Often the best route to success and efficiency in these conditions is proven technologies and strategies.

For over 80 years, e-line conveyance and tools have been refined and improved to become a very reliable means of data gathering and workovers, such as plug setting, debris removal, hardware milling, pipe recovery and so forth.

Challenges

The Arctic region, defined as the area north of the Arctic Circle (66° 33'39" North), is apportioned among eight countries (Canada, Denmark (Greenland), Finland, Iceland, Norway, Russia, Sweden and the US (Alaska). Common to this region are key considerations such as personnel safety and operational stability of equipment in extreme temperatures.

The US Energy Information Administration lists a number of reasons detailing why development of this region may not be economically viable, including frigid temperatures necessitating custom equipment, logistical challenges and heavy investments in infrastructure and the high cost of labor to name a few.

Undiscovered global resources

According to an assessment conducted by the U.S. Geological Survey (USGS), the Arctic may hold as much as 13 percent of the undiscovered, global oil resources, 30 percent of the natural gas resources and 20 percent of the LNG resources, which makes the region increasingly attractive as the world runs out of ‘easy oil'. This translates into 90 billion barrels of oil, 1,670 trillion cubic feet of natural gas and 44 billion barrels of LNG. This means, the Arctic region may hold as much as 22 percent of the undiscovered, technically recoverable, global resources.

Therefore the Arctic is likely to see continued interest for exploration and production. The driver then becomes how to accomplish this successfully and economically. Reducing complexity and uncertainty seems an obvious answer, but in which parts of the workflow?

SPE-166922

SPE-166922 Case studies: E-line heavy workovers in high latitude environments.

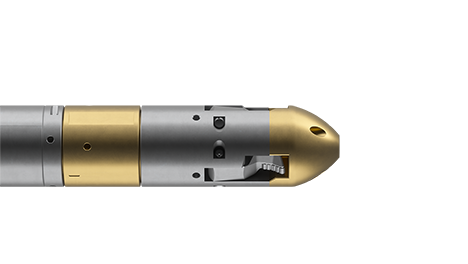

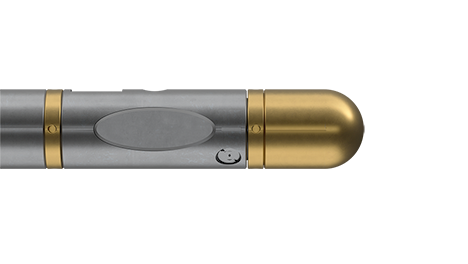

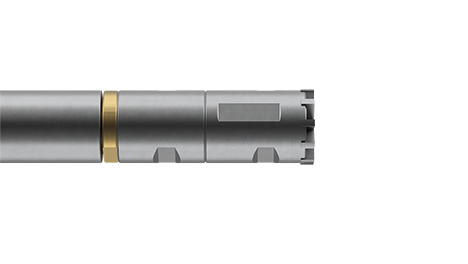

Modern electric line (e-line) capabilities can now accomplish what conventionally would have been rig- or coiled tubing-based workovers. In the North Sea, Canada, Alaska and Russia operators use e-line to perform ‘heavy' workovers; explosion-free cutting of tubulars, scale and debris removal, milling through hardware such as nipples, failed isolation valves and flapper valves, and replacement of hardware, such as gas lift valves and Electric Submersible Pumps (ESP's) in extended reach horizontals.

This paper discusses the benefits e-line tools can bring to accomplish ‘heavy' workovers in a reliable manner in high latitude environments. Several case studies are presented to demonstrate these applications in practice.