Successful obstruction removal in high-temperature gas Well

- Well type Gas

- Deviation 52.16°

- Pressure 2,141 psi

- Temperature 146-154°C

- Clean out depth interval 4,870-4,934m BRT

Background

A client in Indonesia needed to perforate a gas reservoir to increase production. The well was flowing ~ 0.2 MMscf/D, and the reservoir had estimated reserves of around 0.5 BCF. After a 3.5” gauge cutter hung up at 4.60m, a 2.3” pump bailer was run to remove debris. Only 12 liters of debris was recovered from a total of four runs.

The client was hesitant to continue with slickline bailers and sought alternative solutions. Welltec® proposed the Well Cleaner® with the Well Miller® available as a contingency in case hard, or compact, debris was encountered.

Operation

The Well Cleaner recovered 12.6 liters of sand with three bailers and progressed four meters during the first run, but recovery averaged only two liters per run over the next four runs with no depth progress. The recovered sand was contaminated with pieces of metal, and a hard restriction was suspected.

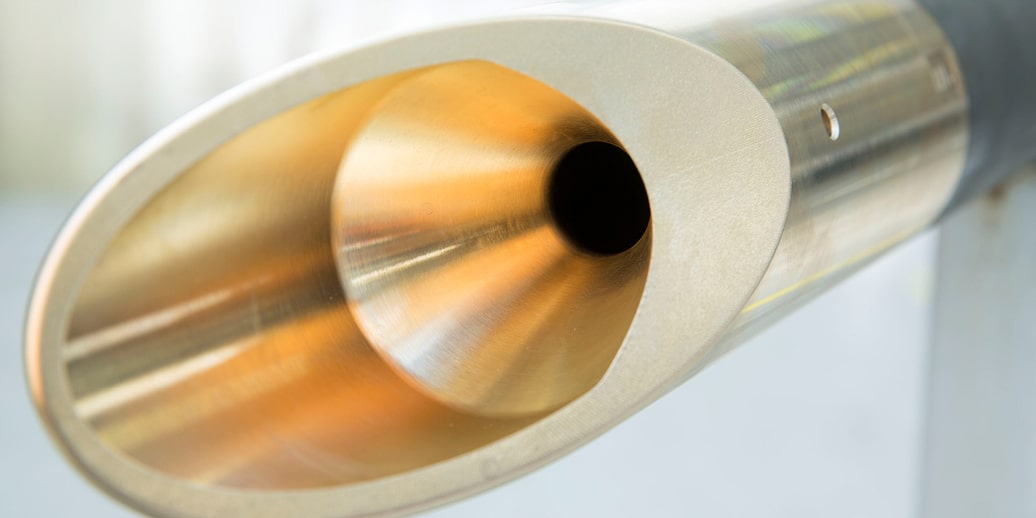

The Well Miller, with a 3.5" tapered scale bit, was run in hole and completed four milling cycles of three-meter intervals. After the milling run, recovery efficiency of the Well Cleaner increased over the next five runs, averaging between 16 and 17 liters per run.

Achievements

The combination of the Well Cleaner and Well Miller allowed the client to regain access to the reservoir for additional perforation, leading to increased production. Welltec’s e-line interventions resulted in a faster, more cost effective solution than alternatives, such as coiled tubing.