Well Stroker® (SRO) delivers enhanced fishing of slickline hammer

- Well type: Oil producer

- Well phase P&A

- Temperature 4°C (seabed)

- Fluid Xylene

Background

Fishing operations often require the application of great force in order to retrieve hardware or tools lost downhole. By providing real-time information on tool performance, these operations can be greatly enhanced and carried out more quickly and efficiently.

An operator in Brazil was attempting to open the S1 valve on a subsea Christmas tree structure as part of a Plug & Abandonment operation, but the slickline Bottom Hole Assembly (BHA) got stuck in the tubing hanger.

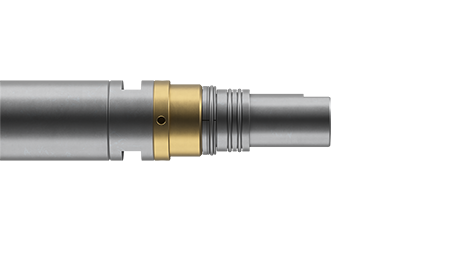

The client initially attempted to fish the BHA using Coiled Tubing (CT), and after a force of 54k lbs was applied (overpull and jarring action), the fish was still stuck in place and now with three dog collars also lost downhole. The client was forced to temporarily abandon the well whilst finding an appropriate fishing solution, and discussions with Welltec led to the proposal of the Well Stroker® 100k with Surface Read-Out 2.0 (SRO).

Operation

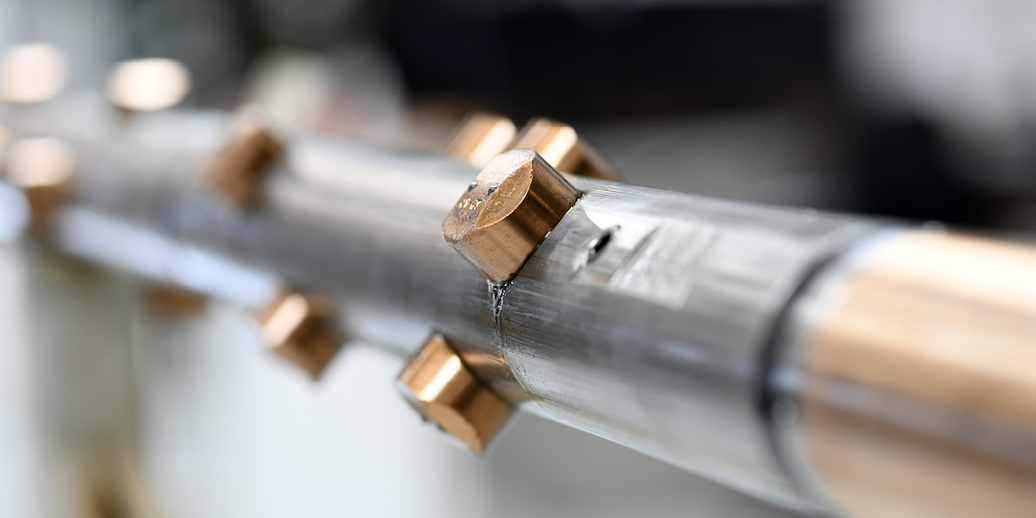

Welltec dispatched multiple tools to the offshore drillship, including the Well Stoker (SRO), Well Tension and Compression sub, and the Welltec Release Device®.

The Well Stroker was run to depth and provided a controlled and gradual application of force, increasing from 20k lbs up to 80k lbs at which point the fish were retrieved.

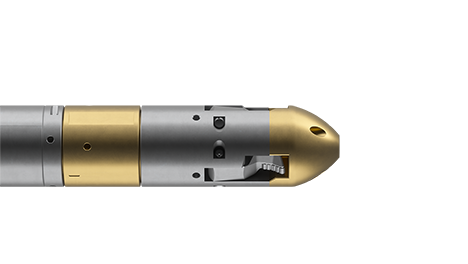

In order to continue abandonment procedures, the 318 Well Cutter® was also introduced and a cut was made just below the tubing hanger to enable the removal of the subsea Christmas tree.

Achievements

A successful fishing operation was carried out using the Well Stroker 100k (SRO 2.0), performed in a hostile downhole environment with the presence of xylene.

The fish were retrieved under a pulling force of 80k lbs and throughout the operation surface readings helped provide full control by indicating tool status in real time.

Real-time data included measurements of pressure, temperature, tension and compression to guide the operation.

The client was very impressed with Welltec’s support and execution, leading to a commitment to run the Well Stroker on future operations.