Production logging and Y-Tool plug operation using Tractor-Stroker combo

- Maximum deviation 86°

- Depth 4,960m

- Temperature 58 C

- WHP 2,277 psi

- Tractor distance 6,412 m

Background

Production logging is an essential data collection exercise carried out by operators to gain an understanding of various characteristics of a completed well, and the way in which fluids behave during production.

In this case from Russia CIS, existing well production was via an artificial lift electrical submersible pump in addition to a Y-tool plug which facilitates operations such as logging. However, in order for logging to take place, the Y-tool plug has to be removed prior to logging, and then set back again after the logging job is complete.

Due to the Y-tool plug being installed at 3,494 m and 60° deviation, it was not be feasible to perform the task using slickline or jarring techniques. Furthermore, Coiled Tubing (CT) was ruled out due to the limited space on the offshore platform, as well as minimum inner diameter restrictions in the well - the necessary slim coil would not have been able to meet target depth.

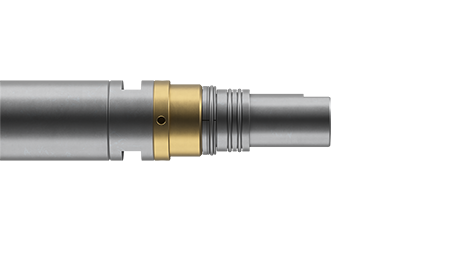

Welltec® proposed a configuration of a 218 Well Tractor® and 218 Well Stroker® toolstring.

Operation

Prior to mobilization, System Integration Tests (SIT) proved that the Well Tractor-Well Stroker combination would be capable of meeting the objective.

Despite a non-standard operation, the toolstring was conveyed to depth and the Y-Tool plug was pulled. Tools were then conveyed through the minimum restrictions and navigated through the 9 5/8” casing using a tandem 218 Well Tractor with extended wheel arms and full control of operations from the surface. The logging while tractoring module allowed for simultaneous well data recording.

The entire operation was completed in just nine hours i.e. successfully pulling the plug to enable logging, passing through all restrictions to TD, recording the log and re-setting the Y-tool plug with production fully restored.

Achievements

As a result of Welltec’s services, the client was able to obtain valuable data to evaluate the well flow profile for the first time and optimize well production.

The entire operation performed by Welltec took eight days in total. A similar operation with the use of CT would have required the removal of the upper completion and establishing well flow with an alternative method, requiring up to 30 days.

Welltec ensured the success of this operation with thorough planning – including SITs – and risk analysis to provide a rapid response and a unique solution.