Welltec® Puncher creates 16 holes in one run

- Tubing punched and cut 7” 32 ppf, L80, 13Cr

- Pressure 422 bar

- Punch depth 3,828.7–3,824.2 m, hole 1–hole 16

- Cut depth 3,837 m

- Temperature 127°C

- Max. depth 21,850 ft MD

Background

In late 2017, a North Sea operator was required to replace one of their Christmas trees (XMT) due to an uncontrolled leak in their well. In order to replace the XMT, the client was forced to pull the upper completion which in turn meant they needed to punch and cut the 7”, 32 ppf tubing just above the production packer, allowing them access to then retrieve the completion.

The client had requested the Well Cutter® as a primary cutting tool due to the clean and beveled cut that is left behind which would allow them to re-enter the well and then pull the deep-set plug, however prior to this part of the operation, the client also needed to punch holes in the tubing to establish circulation. Welltec® mobilized the Welltec Puncher since the original plan was to run both the Puncher and Well Cutter in combination. After further review, however, it was later decided to run the services separately due to evaluating the time required to reverse-circulate gas from the well with a downhole temperature close to 130°C.

Furthermore, the client had initially hoped to use a third-party ballistic puncher but this plan was subsequently aborted due to a misrun with the conventional puncher which was then replaced by the Welltec Puncher

Operation

Welltec’s tools were used successfully for two runs during this operation: the first run with the Welltec Puncher, and the second run with the Well Cutter.

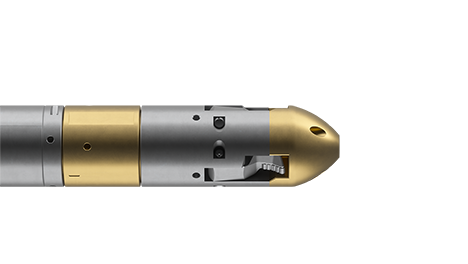

The misrun with the ballistic puncher was thought to have occurred because it is required to fire in the direction of the interface with the tubing. This positioning was an issue because of the well’s 54° deviation. The Welltec Puncher, however, has independent setting arms which ensure that the drilling face is always adjacent and pushed up against the tubing it is to drill through. The Welltec Puncher is a non-explosive tool that equalizes the pressures between tubular strings by drilling a large 12 mm hole in the tubing at target depth.

To achieve the correct positioning, Welltec used a modified centralizer mounted on a three-foot spacer above the Welltec Puncher and Welltec Hardware Scanner (WHS). The WHS monitored and confirmed the orientation of the drill bit during the run. It took just 50 seconds for the first hole to be drilled. All 16 required holes were drilled in under three hours. The average drilling time by hole was approximately 40 seconds.

The Well Cutter was then rigged up with a casing collar locator and run in hole. The position was correlated and the Well Cutter engaged while the tubing was under compression. The cut took only 42 minutes.

Achievements

Welltec’s tools achieved the client’s objectives by punching 16 holes in the tubing during one run, a new record for the Welltec Puncher. Then, the Well Cutter made an efficient, clean cut that left an angled entry guide for future runs in the lower completion.

The Welltec Puncher succeeded generating a flow path with controlled position of equal size and penetration depth holes. This capability introduces new technology opportunities for well intervention, maximizing the likelihood of achieving good circulation.

Ultimately, using Welltec’s tools, especially the non-explosive Welltec Puncher, resulted in a safer hole-punching and cutting option for the client.