Milling out malfunctioning lubricator valve

- Well type 4-1/2” single completion

- Max. deviation 68.18°

- Total depth 10,499 ft. (3,200m) MD

- Max. temperature 194°F (90°C)

- WHP 1,100 psi

- BHP 1,300 psi @ 6,985 ft (2,129m)

Background

After 10 years in service, an operator initiated a re-activation campaign in the Malaysia-Thai Joint Development Area, re-perforating a number of wells to counter declining production.

On one of these wells a malfunctioning lubricator valve would only open at ~80 percent. The faulty valve eliminated running perforation guns and obstructed future interventions; hence, they needed it removed.

The operator decided to use this well as a pilot for future hardware milling operations. Desiring a financially feasible, highly accurate, low risk solution, which would be easy to mobilize, they turned to Welltec® due to our proven track record and service quality demonstrated through successful collaboration on previous projects.

Operation

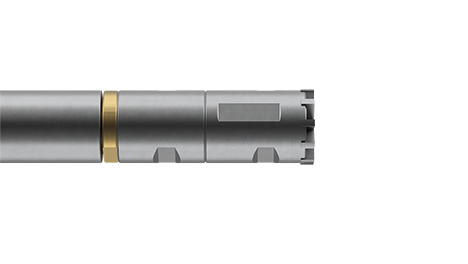

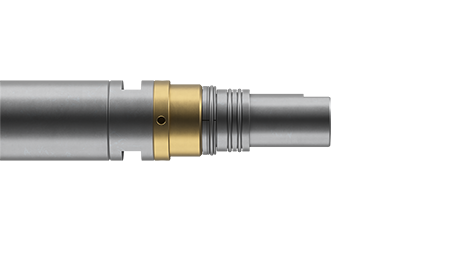

The objective of this operation was to mill through the malfunctioning lubricator valve allowing the operator to retrieve an X-lock from the X-nipple and then re-perforate the well. The valve was located just above a Tubing Retrievable Surface Controlled Subsurface Safety Valve (TR-SCSSV) and a diagnostics run with a four in. OD lead impression block Lead Impression Block (LIB) had confirmed that the valve was only partially open. A custom-built solution employing a Well Miller® 318 and 4.55". core bit was designed to mill through the defective valve and retrieve the fragments.

Conveyed by a Well Tractor®, the toolstring successfully milled the malfunctioning lubricator valve and restored access to the well with substantial cost savings and lower risk compared to coil tubing. Both upper and lower valve coupons were retrieved in two successive runs with the aid of a special ‘catcher design’ in the inner core of the bit. The operator then did a drift run with a 4.515". tubing swage and recovered the 4.51". X-lock from the X-nipple below the lubricator valve. Access was successfully restored for re-perforation and future interventions.

Achievements

Restoring full accessibility to the well in a low risk, reliable manner was accomplished by Welltec’s milling solutions capabilities. The core bit milling technology proved its worth, eliminating the need for expensive, heavy alternatives such as CT or a rig workover.

The operation took a total of six days incl. slickline operations, saving more than a week compared to CT operations and with considerably fewer resources. The milling job itself took a day with an actual milling time of ~two hours.

There were no misruns or lost time incidents. The operator is now able to perform a perforation operation which will increase the production from this well by an estimated eight MMscf/D.

The operation took a total of six days incl. Slickline operations, saving more than a week compared to CT operations and with considerably fewer resources.