Specially developed Dimple Tool with camera locks open faulty Downhole Safety Valves

- Well type Water

- Max. temperature 23°C

Background

An operator experienced several faulty subsurface safety valves offshore Denmark wells. Specifically, they experienced problems locking open 5-1/2” Downhole Safety Valves (DHSVs). The process to lock open (aka lock-out) these valves typically involves setting a “beer can” across the flapper. In one case, a leak in the flapper could not be repaired and resulted in the lock open tool setting with a loose base spring, making it nearly impossible to fish.

The tool failed twice when the beer can was present, forcing the operator to fish it. Finally, the operator decided to set a new DHSV.

Operation

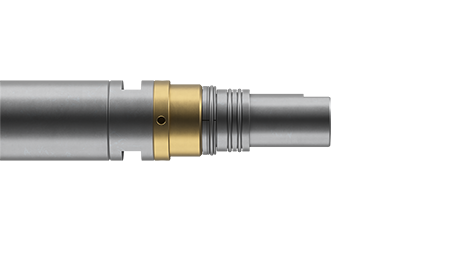

Welltec® began developing a solution to this common problem and envisioned a tool that could deform the flow tube of the DHSV when it is straddling the flapper, thereby locking it open. Welltec designed a new, universal solution specifically for this purpose. The new tool deforms—or dimples—the tubing by jarring a piston/ball out into the flow tube, enlarging the flow tube and disabling flapper movement.

Welltec then performed a Systems Integration Test (SIT) to qualify the tool and prove its effectiveness. The SIT confirmed that the new solution fit its designed purpose and proved that the tool could apply enough force to deform the flow tube without damaging it. The SIT also showed that the tool could correctly and reliably correlate its position within the tubing.

Welltec has since successfully run this new dimple tool for the client in two wells. In both cases, the tool solved the issue by locking open these faulty DHSVs.

Achievements

This solution enabled the client to easily perform the lock open procedure with no issue. Further, the new dimple tool system saved the client time by using reliable electric line depth control to position the tool, reducing confusion, misruns and mistakes which often leads to more maintenance and interventions on the DHSV.

Welltec developed this innovative solution to solve this specific problem for the client but ensured that the tool was universal and could be used on different types of DHSVs.

After the first operation, Welltec further developed the tool and added a downhole camera to confirm correct dimpling in the same run. This development saves the client time and costs by avoiding two additional runs with cameras.