Power Suction Tool performs heavy clean-out via e-line

- Well type Producer

- Location Gullfaks, Norway

- Max. deviation 85°

- Depth 2,747 m

- Max. temperature 156°F (69°C)

- Max. pressure 245 bar

- Distance tractored 1,100 per run

Background

Clean-out operations are commonplace – an everyday necessity for maintaining levels of well production. In cases where downhole debris is heavy in presence, clean-out jobs tend to be carried out via the use of Coiled Tubing (CT). Any means by which time can be saved yet still deliver a high-level of performance is always preferred.

Challenged by Equinor to make more efficient, large volume cleanout e-line tools, Welltec® developed the 414 Well Cleaner® Power Suction Tool (PST) which significantly improves e-line cleanout capability via:

- Higher flow rate and pump pressure compared to previous generation

- Real time monitoring and QC of tool performance

- Surface controlled pump speed

- Larger volume bailer tool sections

- More powerful pump allowing increased bailing capacity and filling percentage

In this case, a producer well on the Gullfaks field operated by Equinor (Norway) had approximately 300m of continuous sand distributed along the well. To evaluate how the new e-line conveyed solution would perform, Equinor opted for the 414 Well Cleaner® Power Suction Tool (PST).

Operation

Limited by rig-up length, the PST was set up with seven 4.25” OD bailer sections (80-liter capacity).

The operation can be summarized in three main aspects:

Downhole

The Well Tractor® conveyed the PST approximately 1,100 m per run, covering up to 30 m per minute. Clean-out procedures were followed at depth in order to maximize filling capacity, and after an average 2.5 hours per run spent at depth, equipment was pulled out of the hole.

Between runs

As operations took place to lay down the first Bottom Hole Assembly (BHA), the subsequent BHA was simultaneously prepared in order to be ready as soon as required.

Emptying the bailers

When handling the bailers/debris there can be a risk factor of exposure to Benzine. Thanks to the pumping capability of the tool, this risk was minimized by circulating water through the debris when the tool was in the lubricator. Emptying of the bailers was also carried out in a coordinated effort with downhole operations, further facilitating a tandem approach whereby empty bailers were immediately ready at the start of each run. Efficient bailer cleaning was achieved by an optimized number of crew and the strong bailers allowing for one-piece pick up/lay down.

This approach to operations facilitated the most efficient use of time possible.

Achievements

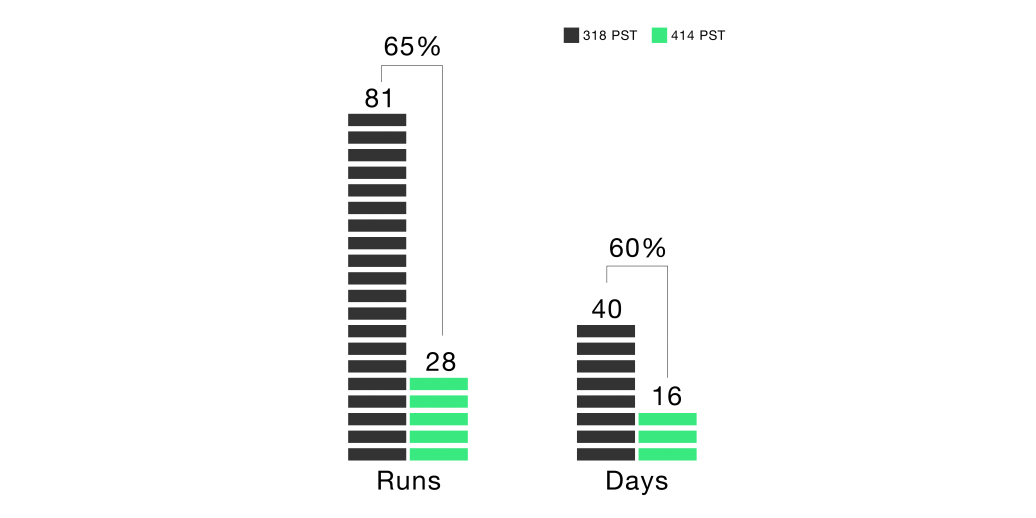

The overall success of this operation lies in the consistency of the e-line solutions which were provided. The well was clean within the time allowed by the budget, and the primary well objective was achieved. Welltec removed more than 1,700 liters (3 tons) of compact sand within 28 runs in just 16 operating days. Across those runs, bailer capacity reached 100% on 11 occasions, averaging at 83%.

The new PST provides Equinor an additional cleanout option which can be quickly mobilized, operated within a small footprint, at low HSE risk.

The graph below illustrates how many runs and days Equinor saved in this operation by using the new 414 PST compared to the existing 318 PST.

Runs by Well Cleaner PST 414 vs 318