Increased efficiency in extreme well environment

- Well type Gas producer

- Max. well deviation 91°

- Max. depth 18,725 ft

- Max. pressure 12,000 psi

- Max. temperature 310°F

- Distance tractored 8,490 ft

Background

Unconventional resource exploitation is gaining momentum in the Middle East as demonstrated by this case which describes an operation in a new, deep, high pressure gas reservoir.

In this well, the client needed to test the casing integrity and perform a perforation. Because of the environment, 310°F (154°C), 91° horizontal well, standard wireline conveyance was not an option. Since the well was designed as a multi-stage frac project, pump down logging wasn’t feasible and Coiled Tubing (CT) was deemed to be too time consuming.

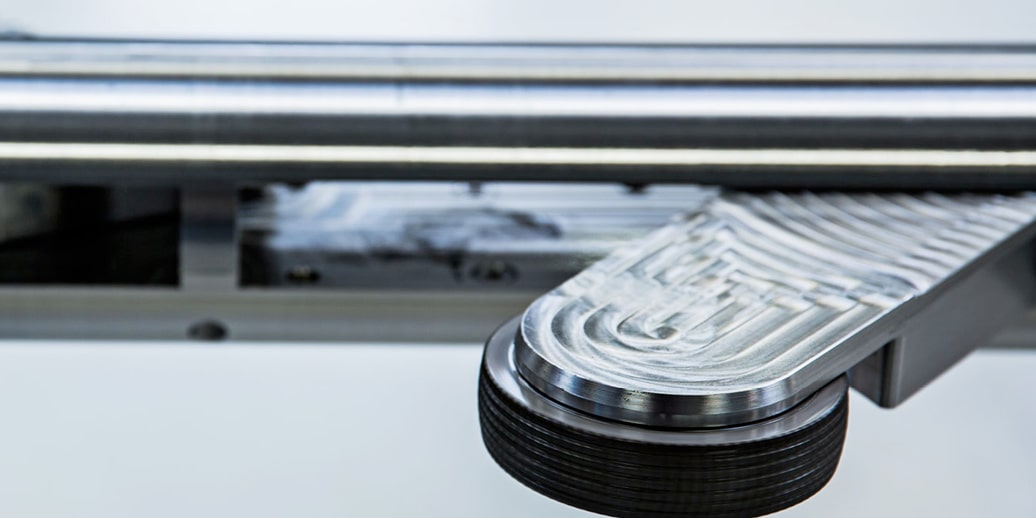

A Well Tractor® would, however, overcome all these challenges while also offering accurate depth control, improved log quality and lower costs.

Operation

Multiple feasibility studies were carried out to demonstrate to the client that the Well Tractor 318 would do the job. Because of the recent advances in DC electronics the Well Tractor proved able to execute the job under the extreme well conditions.

Prior to the operation, Welltec® and Halliburton collaborated together to fully test the newly designed electronics. This included heat testing and ensuring the electronics were compatible with the Halliburton equipment and cable.

The job was composed of two runs; the first to convey a cement bond log and a multi calliper imaging tool. Here the toolstring was run in hole with the Well Tractor and logging tool to the kick-off point at about 15,600 ft, at which point the Well Tractor was engaged and conveyed the toolstring to 18,725 ft.

On the second run, the Well Tractor conveyed a 3 3/8″ gun to perforate the desired zone at 18,725 ft. In total, the Well Tractor covered a distance of almost 8,500 ft.

Achievements

This was the first time the new DC package was used in the Middle East, but it clearly demonstrated the value of the technological development. The Well Tractor worked flawlessly despite the high temperatures, high well deviation and a 18,725 ft extended reach section.

Using Welltec’s e-line solution the operator achieved better data quality by utilizing more advanced depth determination tools. In addition, Welltec reduced costs and increased operational efficiency by saving valuable time. Last but not least, the environmental impact and risks were reduced as the e-line solution eliminated mobilizing a rig.

This was the first time the new dc package was used in the middle east, but it clearly demonstrated the value of the technological development.