SCP prevention

C Annulus

Methane emissions prevention

At surface and within the casing annulus

Solution

16 WAB with differential valve

A client in the Middle East had faced challenges with conventional Differential Valve (DV) stage-cementing tools and inflatable packers when performing second-stage cement within the C annulus (13-3/8" by 18-5/8").

The problems stemmed from the inflatable packers failing to seal, and/or the DV tool not fully closing. Poor second-stage cement operations inevitably lead to Sustained Casing Pressure (SCP), and in many cases the SCP is charged by methane gas leaking to the surface as a result of the poor cement sealing.

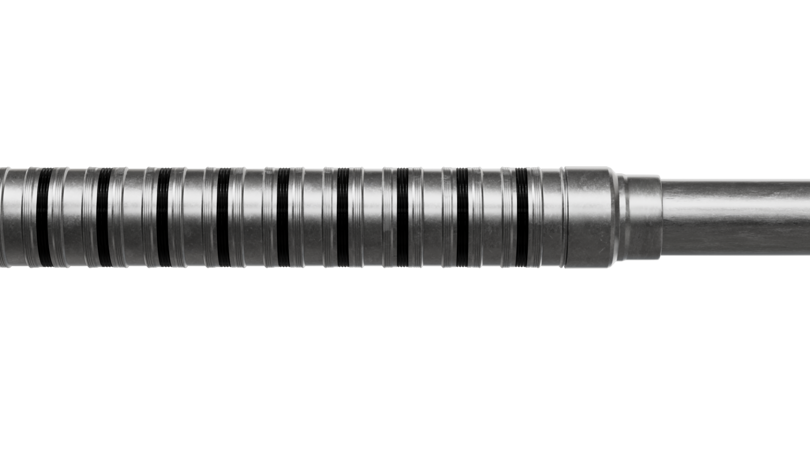

Through discussions with the client, Welltec® offered to provide a more robust solution in the form of a Metal Expandable Packer (MEP), integrating a 16" Welltec Annular Barrier (WAB) with a Citadel DV tool.

This combination was qualified to ISO14310 V0 leak criteria in Denmark, with surface integration testing (SIT) completed at the Welltec manufacturing facility in the Middle East. This combination of products delivers a high level of seal robustness to secure the second stage cementing process, and ensures well integrity to prevent C annulus SCP.

The combination of the DV tool and MEP was installed on the 13-3/8” casing, run in hole and positioned shallow of the 18-5/8” shoe. The first stage cement was pumped, plug bumped and 4,000 psi was applied to the plug to expand the MEP, sealing off the annulus between the 13-3/8” and 18-5/8” casing below the DV.

The DV opening plug was deployed, seated, and 440 psi was applied to open the DV tool. The second stage cement was pumped, the closing plug was installed and seated via 870 psi, closing the DV tool. To confirm the DV tool was closed, 500 psi was applied within the 13-3/8” casing and held for 15 minutes.

The Welltec system combining an MEP and DV was successfully deployed and enabled drilling operations to progress to the 12-1/4" section. To date, no SCP has been observed within the C-annulus.

The customer representative described the operation as "flawless". The choice of Welltec's products was based on the robustness, reliability, and track record, reinforcing the customer's confidence to utilize the system. Future systems will be manufactured and assembled at the local Middle East facility.

This solution for implementing effective measures to prevent SCP and methane emissions within the casing annulus provides a significant contribution toward the client achieving their Net Zero targets and promoting sustainable environmental practices.

WAB® for Well Construction & Integrity (Welltec® Annular Barrier)

CAPEX effective, enhanced well integrity via metal expandable packers