Well type

Water injector

Stuck depth

266m / 1,871ft

Deviation

94°

Temperature

54°C / 130°F

During a wellhead maintenance campaign in Qatar in May 2021, the sub-surface safety valve (SSSV) of an injector well failed several attempts at an inflow test. The operator decided to perform an SSSV acid soak sleeve during an intervention campaign in July 2021. After clearing out scale, the acid soak sleeve was run into the well and set in the SSSV. The acid syringe was run in the well and deposited the acid behind the SSSV soak sleeve. Personnel observed high overpulls during recovery, and the acid syringe would not pull free.

Jarring on slickline was unsuccessful, and the crew suspected that scale had fallen on top of the toolstring. The wire parted at surface, and the operator decided to drop a cutter bar and recover the wire from the well, leaving the toolstring downhole. Braided line was subsequently rigged up and used to attempt recovering the toolstring and the acid syringe. Fishing power jars fired at approx. 3,400-3,500 lbs to recover the toolstring and syringe but were unsuccessful.

After these unsuccessful attempts to recover the stuck toolstring and acid syringe, the operator needed a fast and reliable solution for this fishing operation. Though coiled tubing (CT) was an option, the method presented significant costs and required substantial time. The client wanted to use an e-line intervention because of the added operational precision and control. Additionally, the client was aware of the Well Stroker’s capabilities from a high profile fishing operation in another well in 2018.

The client and Welltec® teamed up to recover the toolstring and acid syringe at 1,871 ft (266 m) and restore the functionality of the SSSV so the well could be brought back online and restore well integrity.

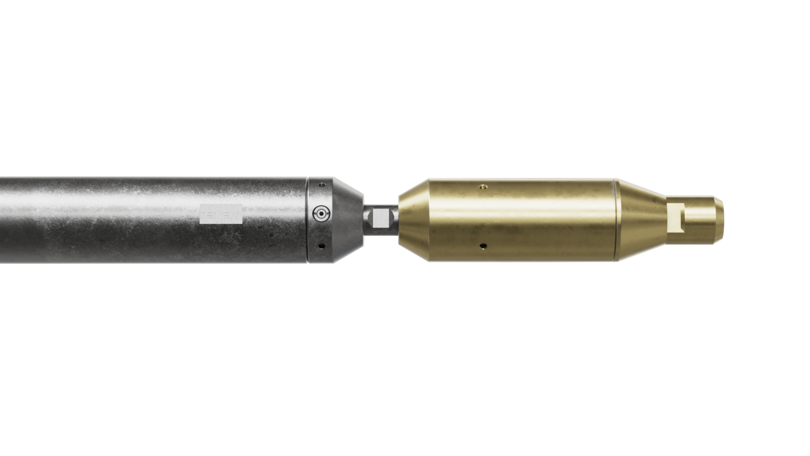

Welltec began by completing a systems integration test (SIT) to confirm the functionality of the Well Stroker 100k being able to release the 1.875” power jar of slickline in one up stroke. After the successful SIT, the tool was mobilized to the well site.

The toolstring was RIH and latched on to the top of the fish. The force for the stroker was increased from 10k pounds to 40k pounds as the piston was making progress and the fish was moving. Personnel placed an overpull on the wireline unit, but, after the tool was switched to static mode, the piston was extending automatically, caused by the weight of the fish attached to the bottom of the string. This issue prevented it from moving upwards any further.

After several attempts, it was decided to shear the pins on the pulling tool by stroking down. The tool came free of the fish, but the fish went back into the initial stuck position. The subsequent run followed the same procedure, but, this time, the force required was lower and the top section of the fish came free. The final run was performed by applying up to 50k lbs to retrieve the bottom part of the fish.

The proposed toolstring configuration worked well in these challenging conditions. Despite the challenges, after four runs and more than 70 strokes in total, the two sections were pulled out of the hole after being stuck there for nearly a year.

This successful operation demonstrated the innovation and robustness of the Well Stroker’s design. The most important characteristic of the tool was the ability to operate the anchors and piston independently, along with realtime adjustment of force and piston movement, allowing the client to adjust the procedure depending on the status of the operation.

Further, from the beginning, the SIT was performed in the Welltec base during the initial stage of the planning, showing that the operation was feasible. This SIT gave the team confidence and allowed the client to proceed with the e-line option and discard the CT option.

The total operation was executed in a short period of time, especially when compared with a typical CT operation. The whole operation was conducted in approximately 5 days, far more efficient than the two to three weeks needed for a typical CT operation. Additionally, e-line is safer for personnel and the environment and, because of its light weight, presents an easy rig-up and rig-down procedure.

Using the Well Stroker 100k on e-line allowed the client to monitor all the details of the operation and make decisions in real time. After retrieving the complete fish, the client could perform all the tests required to evaluate the conditions of the well and put it back on injection in a reasonable amount of time after being down for a year.

“The fishing got more complicated than expected, and you guys faced some issues with the tool, but, in the end, you managed to complete the operation in a safe manner per usual. We appreciate the effort, the support, the follow up, and the prompt actions taken since the beginning. Not all the companies do that!”

Client feedback