Well type

Geothermal producer

Renewables

Welltec pilot success in renewables market segment

Engineered workover

Cost savings of USD 8 mm vs drilling of new well

High temperature application

To sustain up to 550°F at full production

Capex-effective

Well-rejuvenation methods

Location

Philippines

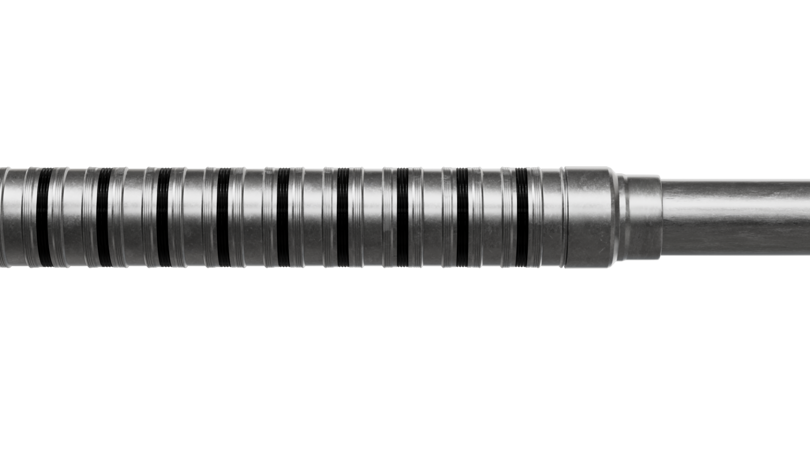

A prolific geothermal producer (23 MW) had to be shut in, due to significant failures within the 13-3/8” casing. After consultation with our Asia Pacific team, Welltec® offered a 1214 Welltec Annular Barrier (WAB®) solution that would facilitate the pressure-tight base for hydro-static support to the column of cement slurry placed above it. This would negate any contamination during the curing process, resulting in a good cement operation.

The 1214WAB would also offer anchoring support to the casing string in the event of thermal contraction or expansion during production or shut-down operations.

A standard 1214WAB was adapted to incorporate non-elastomeric isolation valves and burst discs to facilitate bleed-off in the event of high-pressure steam build-up behind the casing. WAB placement was directly above the 9 5/8” casing tailpipe and set within the existing 13 3/8” casing. Second stage cementing was performed above the installed 1214WAB.

During deployment, water flooded the well to keep temperatures ≤ 212°F – full production temperatures would be 600°F. The 1214WAB supported the cement column during curing and prevented free-water/acid from contaminating the cement or reaching the surface.

This operation represents the first time that a WAB was used to revive a geothermal well. This job also marked the first time Welltec provided services for a geothermal well (Philippines), and deployed the WAB with second stage cementing equipment in Asia.

To drill a new well would have cost the client between USD 9 million and USD 12 million.

Welltec’s solution enabled the client to execute life-of-well, CAPEX-effective well-rejuvenation measures, proving the value of engineered well remediation techniques.

WAB assembly was adapted to incorporate a high-temp sealing system, non-elastomeric isolation valves and incorporated burst discs to bleed off high-pressure steam within an application that will reach 600°F at full production.

Incorporating the high temperature WAB simplified the installation process when compared to alternative products with far more complex setting procedures.

Client feedback

WAB® for Well Construction & Integrity (Welltec® Annular Barrier)

CAPEX effective, enhanced well integrity via metal expandable packers