Well type

Oil & gas producer

Reservoir type

Sandstone

Product placement

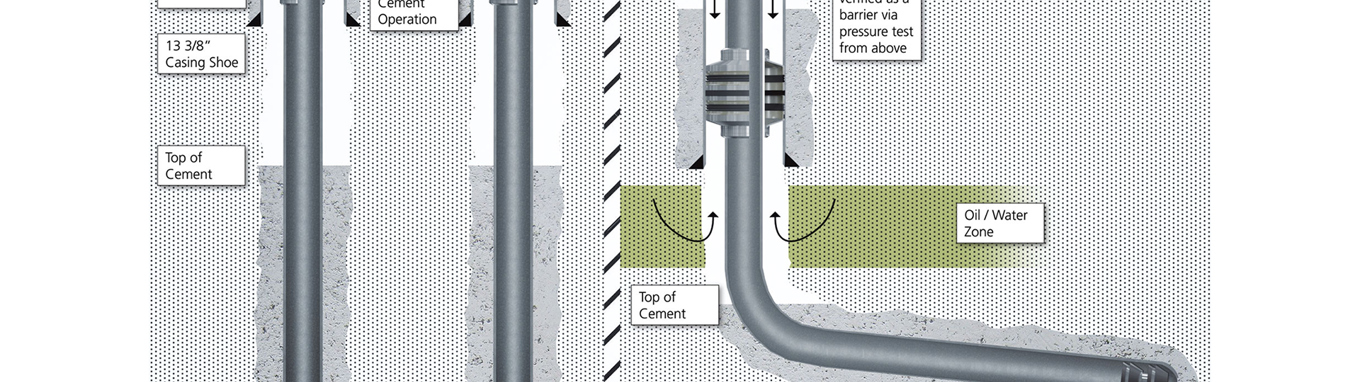

Within 13 3/8" casing

Compliance with norsok D10

Confirmed without further need for dispensation

V0 1214WAB set within 13 3/8" casing

Enables preferred primary cement operation

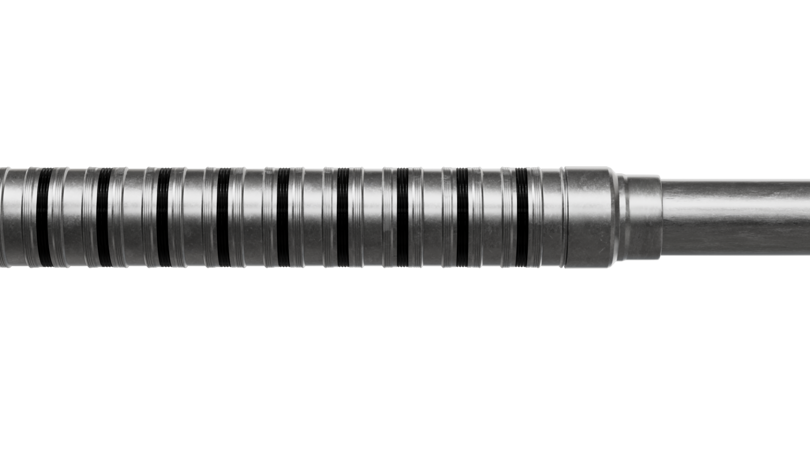

WAB qualified to 5,000PSI IS0 14310 V0

Leak rate criteria

WAB rotational capability

Enhances primary cementing operations

Location

Norway

A Norwegian IOC sought a solution to mitigate against Sustained Casing Pressure (SCP) build-up within the B annulus. This phenomenon is the result of gases (primarily methane) that build up at surface equipment level and eventually need to be released resulting in harmful emissions to the atmosphere.

With these concerns in mind and given the distance and formation conditions, the client, mindful of environmental impact, wanted to avoid bringing top of cement to the 13-3/8” shoe.

The solution had to go beyond SCP mitigation with client policy dictating the need for a fully qualified ISO 14310 V0 well barrier.

The 1214 Welltec® Annular Barrier (WAB®) was selected to provide the required V0 seal and simultaneously eliminate SCP and methane emissions by forming a gas-tight seal within the casing, isolating the formation below. Load simulations for the 9-5/8" casing were meticulously calculated, ensuring that the deployment of the WAB would not only meet the load envelope but also achieve V0 leak rate criteria at 5,000 psi of expansion pressure.

The 1214 WAB was successfully deployed with the 9-5/8" casing and set as a standalone solution at the conclusion of primary cementing, carried out within the 13-3/8" casing.

Primary well barrier verification was completed via pressure test from the surface, within the B annulus.

The WAB solution eliminated SCP and ensured that methane gas remained within the formation, ensuring that the completion aligned with the client’s commitment to environmentally conscious energy practices.

Subsequent primary well barrier verification confirmed the effectiveness of WAB technology.

Stringent requirements were met in terms of V0 leak rate criteria, in full accordance with ISO 14310 qualification.

V0 rated WAB secures life of well integrity and facilitates CAPEX effective well construction.

Welltec

WAB® for Well Construction & Integrity (Welltec® Annular Barrier)

CAPEX effective, enhanced well integrity via metal expandable packers