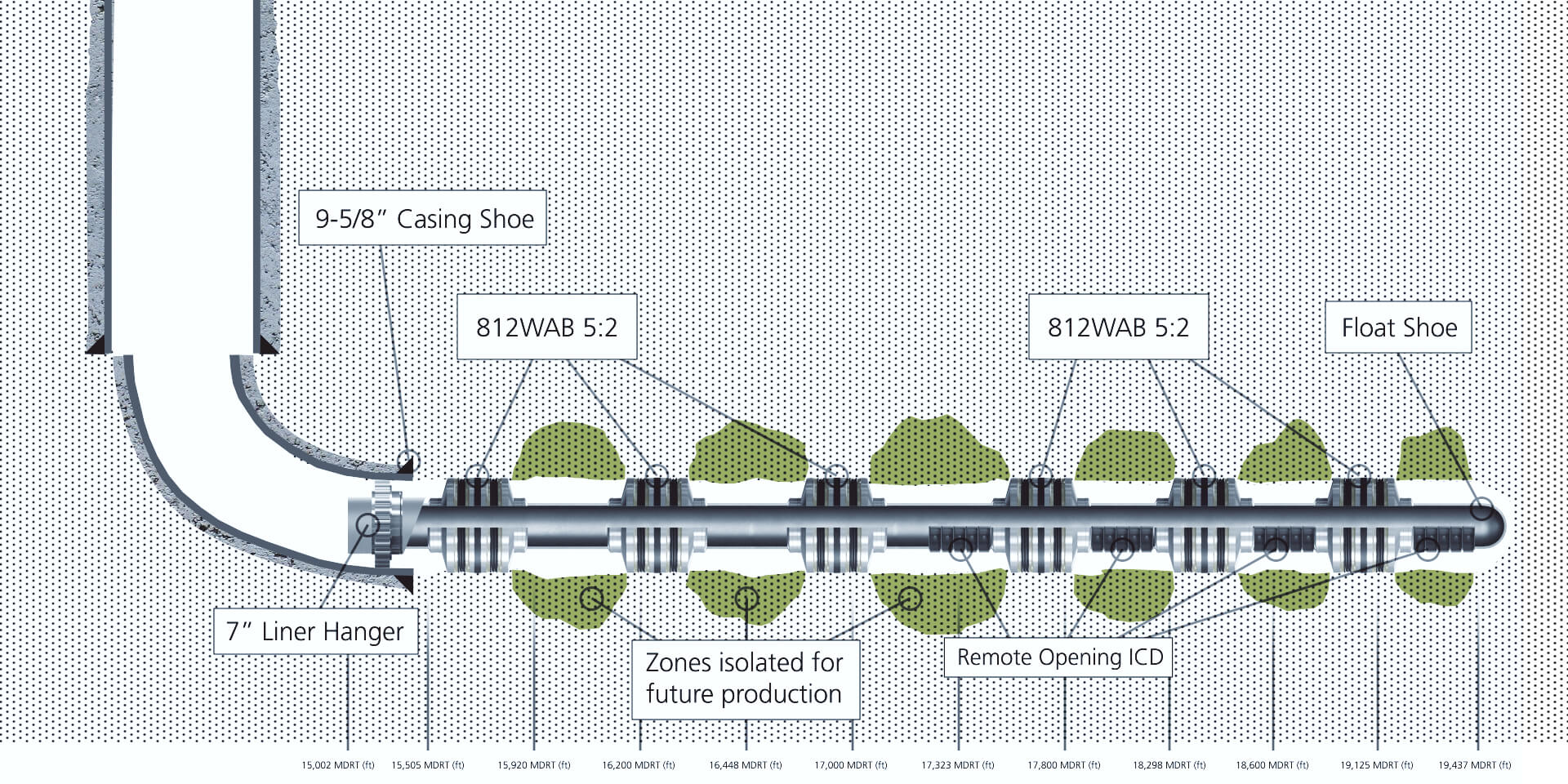

Welltec® Annular Barrier (WAB®) for horizontal reservoir isolation

- Well type Oil producer

- Max deviation 90 degrees

- Total depth 19,750 ft / 6,020 m

- Horizontal section: 14,079 ft / 4,291 m

- Max temp.: 79°C / 175F

Background

A client in Saudi Arabia was experiencing losses with several wells across the same oil producing field.

The issue stemmed from an inability to isolate the reservoir section of the wells, and horizontal trajectories were exacerbating the situation.

With the persistence of this developmental issue, a conventional off-bottom cement job would not be a feasible option on a new well due to the occurrence of loss zones when deploying the liner, as well as a general difficulty in sealing the reservoir of the extended reach interval.

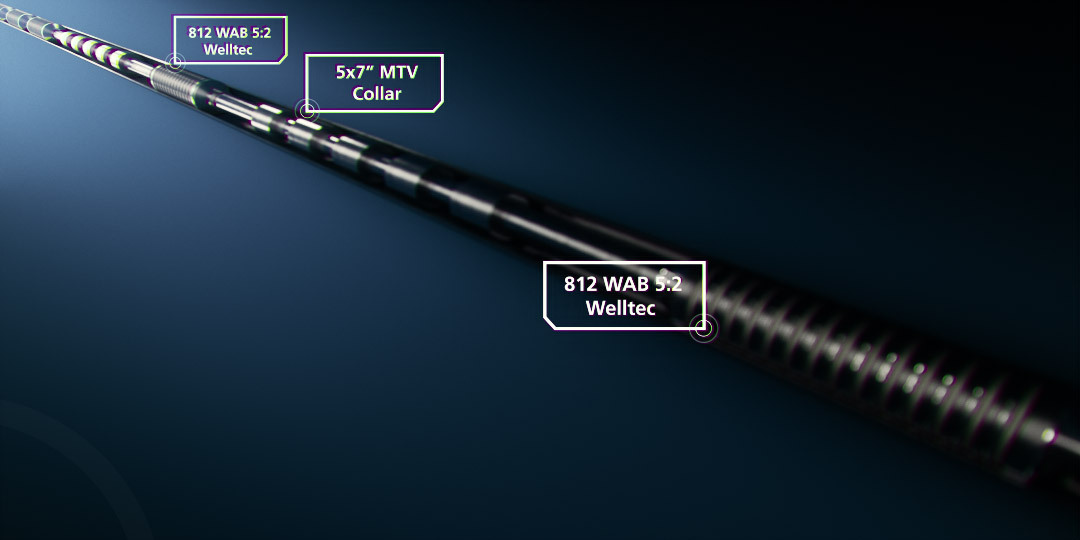

The client had been trialing the Welltec® Annular Barrier (WAB®) to achieve zonal isolation in a lower completion scenario and was aware of its potential as a solution.

In choosing a WAB, the client would receive a fully rotatable metal expandable packer solution which can also be deployed without cement to achieve isolation.

Operations

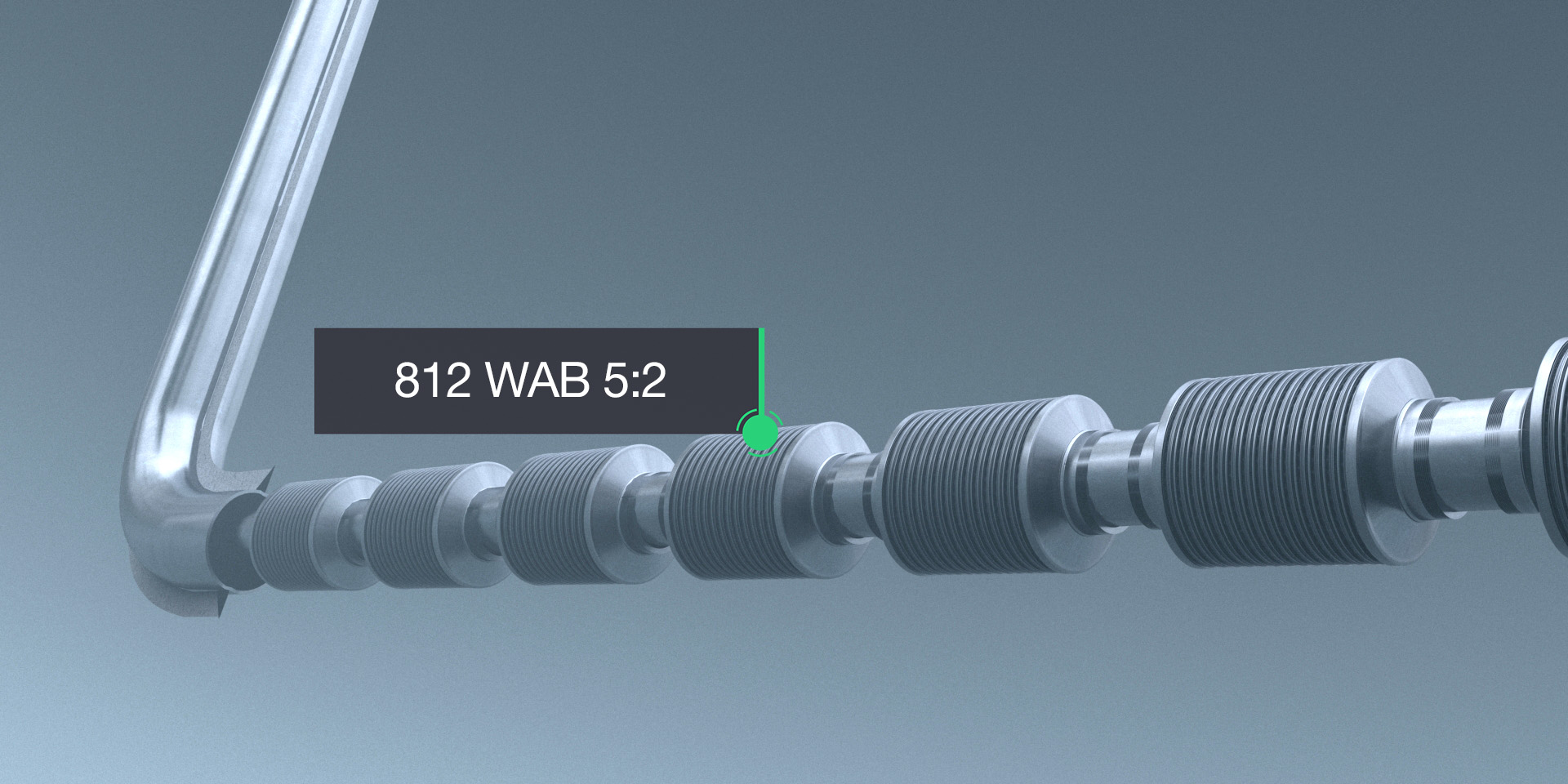

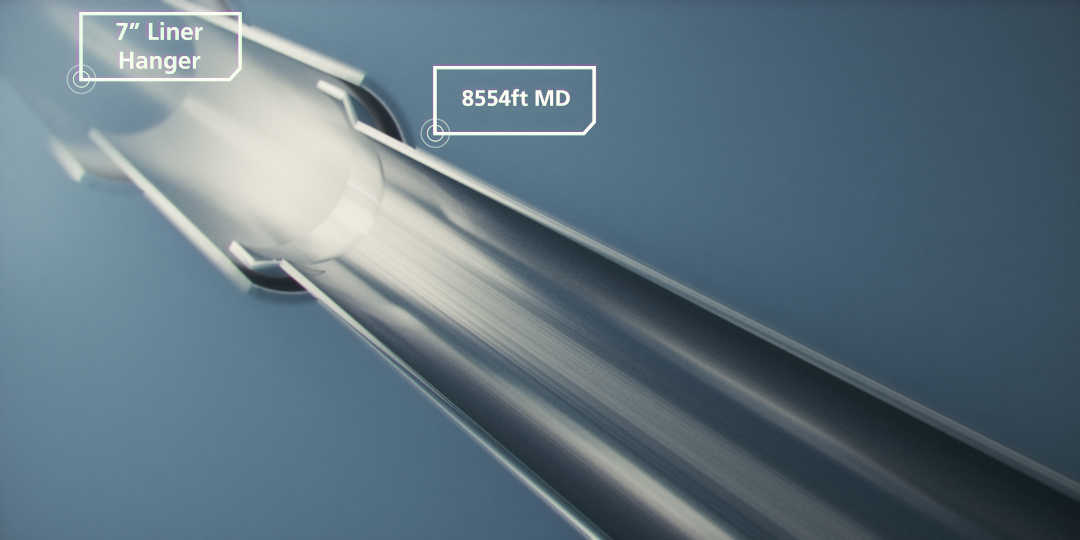

The lower completion assembly was fitted with six WABs and run to depth. With a 1.5” ball dropped, pressure was applied at 2,500 psi and the liner hanger was set. The ball was blown through at 3,200 psi (to regain circulation) and a larger 1.75” ball was dropped.

Pressure was applied to 3,000 psi in order to trigger the remote opening of Inflow Control Devices (ICDs), subsequently increased to 5,000 psi to set and expand all six WABs simultaneously.

Successful expansion of the WABs was complete in less than 30 minutes and confirmed by a stable setting pressure and volume calculation.

Achievements

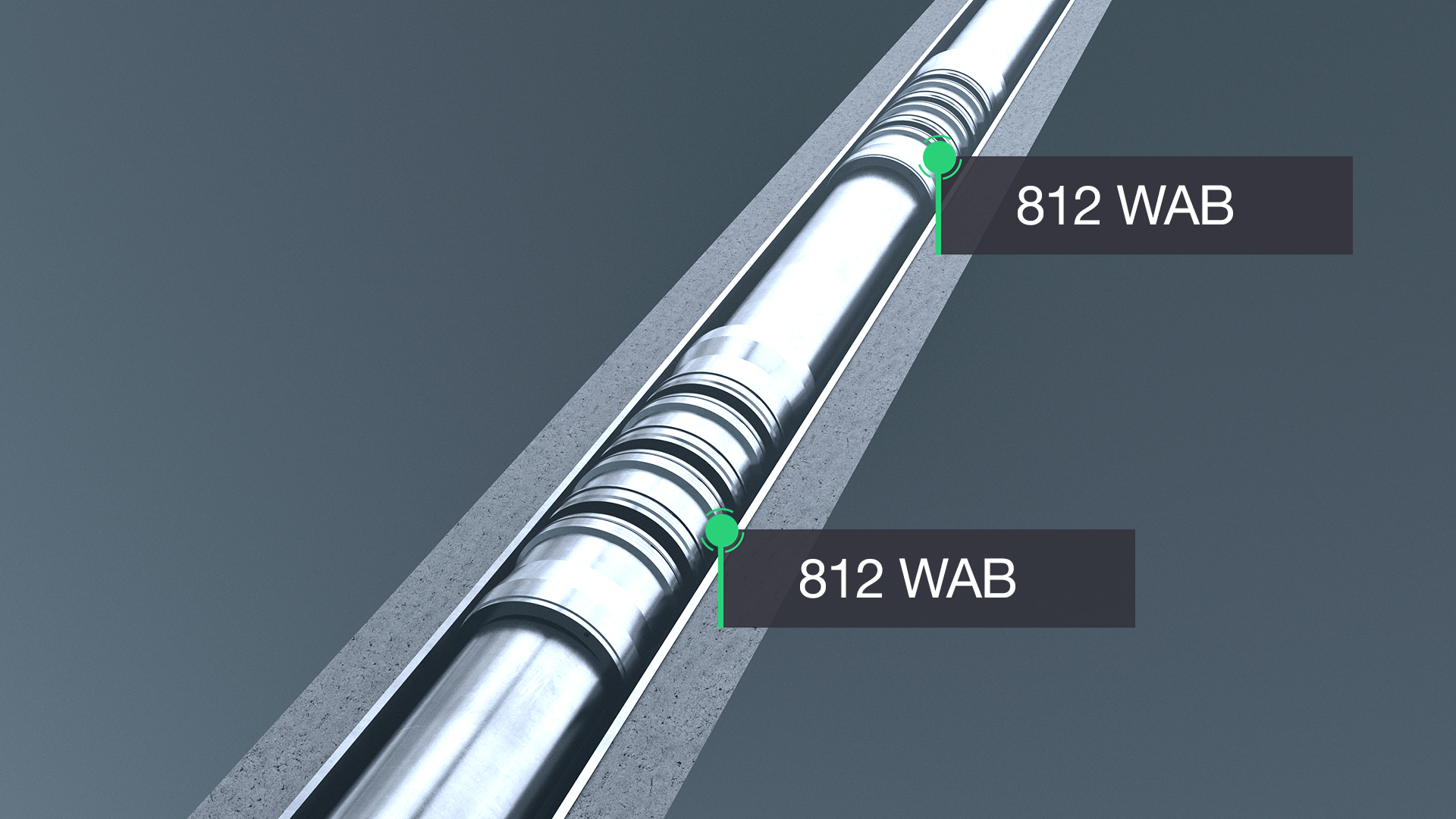

The primary goal of zonal isolation was achieved via the installation of six WABs in the completion, and losses were thus prevented.

Furthermore, the WABs eliminated the need for cementing operations that would have been executed in several time-consuming stages.

An effective solution was provided without the associated risk of fitting conventional mechanical open hole packers and swell packers to the long horizontal section, whereby isolation could have been lost in the event of damage during deployment.

The WABs versatility in application allows for future well design scenarios offering major CAPEX savings and lower OPEX costs, and the option to set within the casing means that wells can be completed regardless of whether target depth is reached.

Well schematics