First North Sea Installation of Welltec® Annular Isolation replaces cement liner

- Well data Water injection

Background

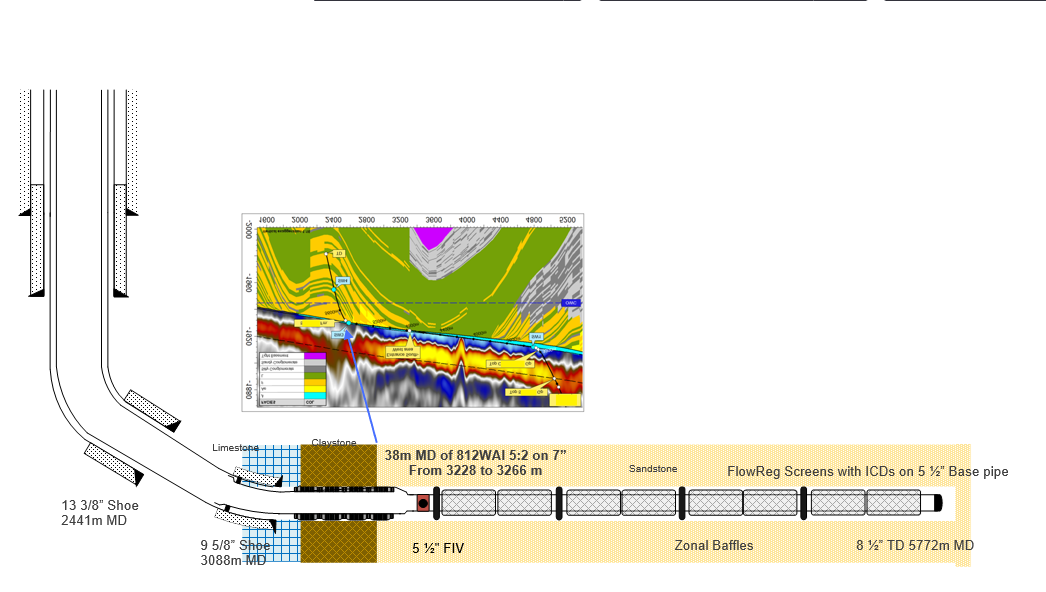

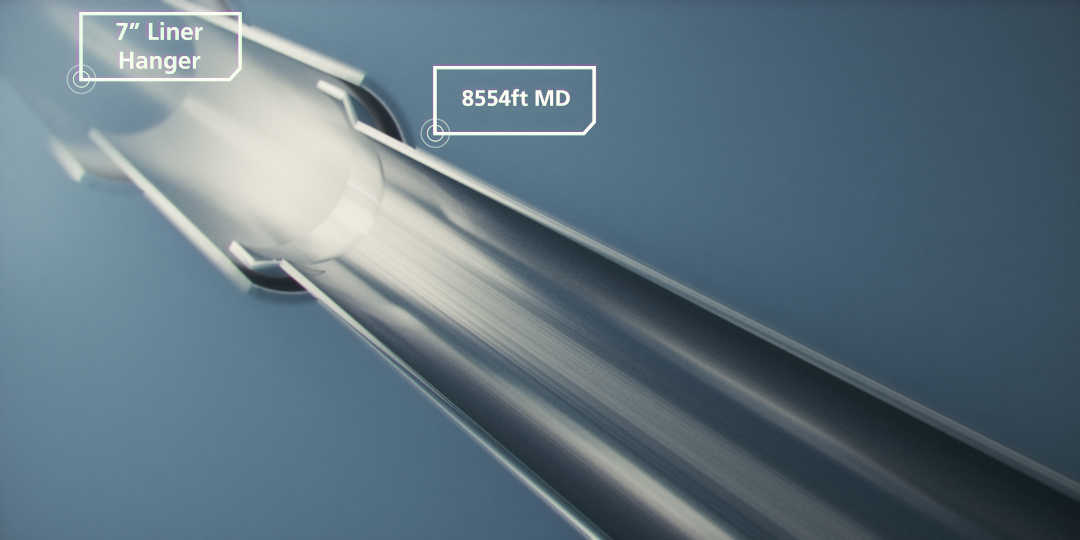

Lundin, operating in the North Sea, was drilling a water injector for support to nearby oil producers. The original well design included a conventionally cemented liner to achieve the annular barrier. However, finite element analysis (FEA) modeling and load calculations illustrated that cement could be replaced by Welltec® Annular Isolation (WAI™) technology, facilitating annular isolation and anchoring while allowing the reservoir to be drilled as one section instead of two.

Typically, the operator would drill the cap rock with 12-1/4” and land the 9-5/8” shoe within the base of the cap rock above the top of the reservoir. Because of a reduced safe fracture gradient (SFG) in the cap rock, a short 7” liner and cement operation would be required to secure the primary barrier across the cap rock. This short 7” liner presented some challenges, including the cost of drilling a short section of 8-1/2” and running the 7” liner, achieving an effective cement seal due to the low volume of cement and high well deviation, and a 6” hole and 4-1/2” liner across the reservoir, which would significantly affect future injection capacity.

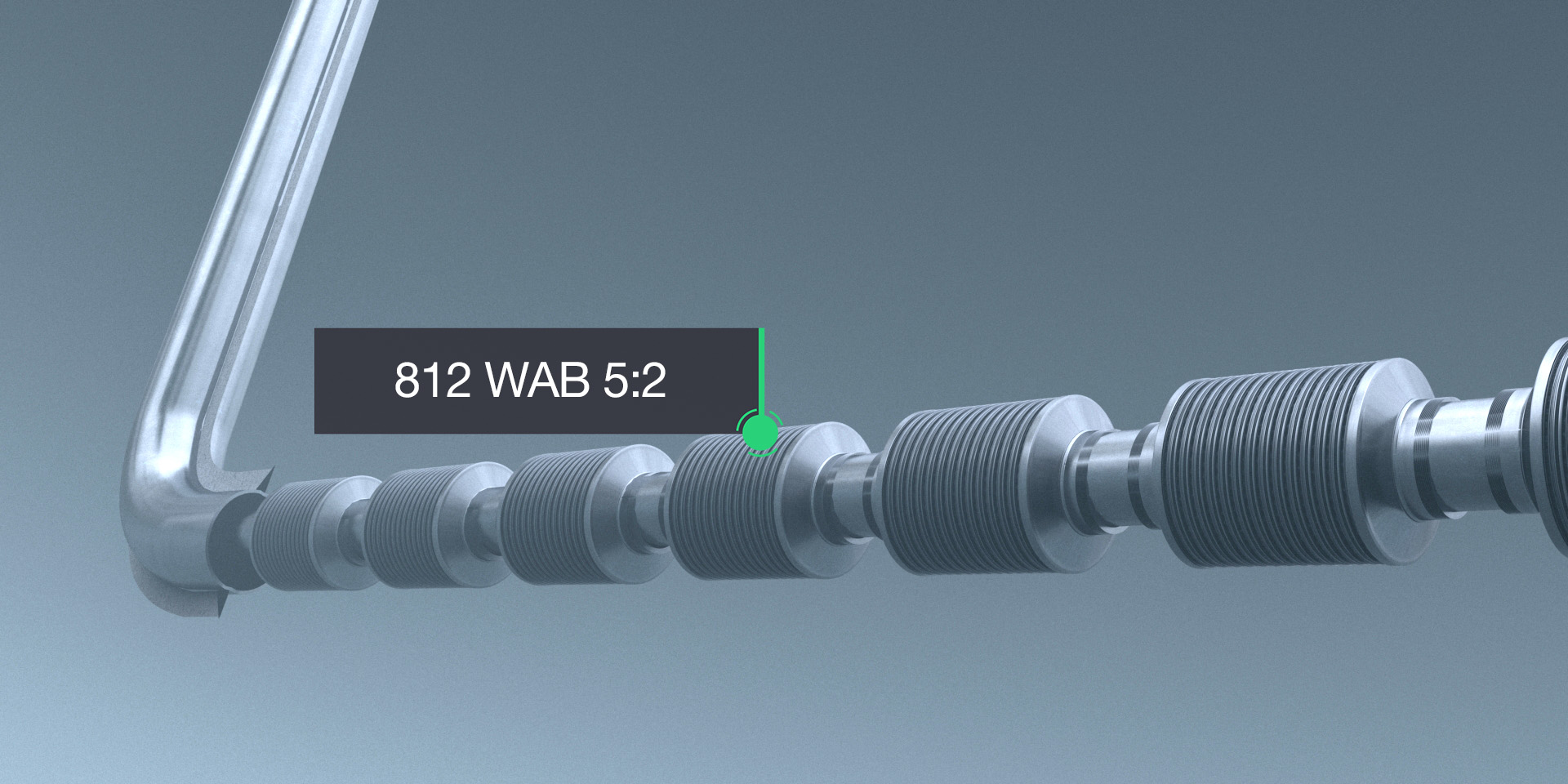

Welltec proposed to substitute the short 7” liner with WAI. The WAI would then form part of the primary well barrier.

Operation

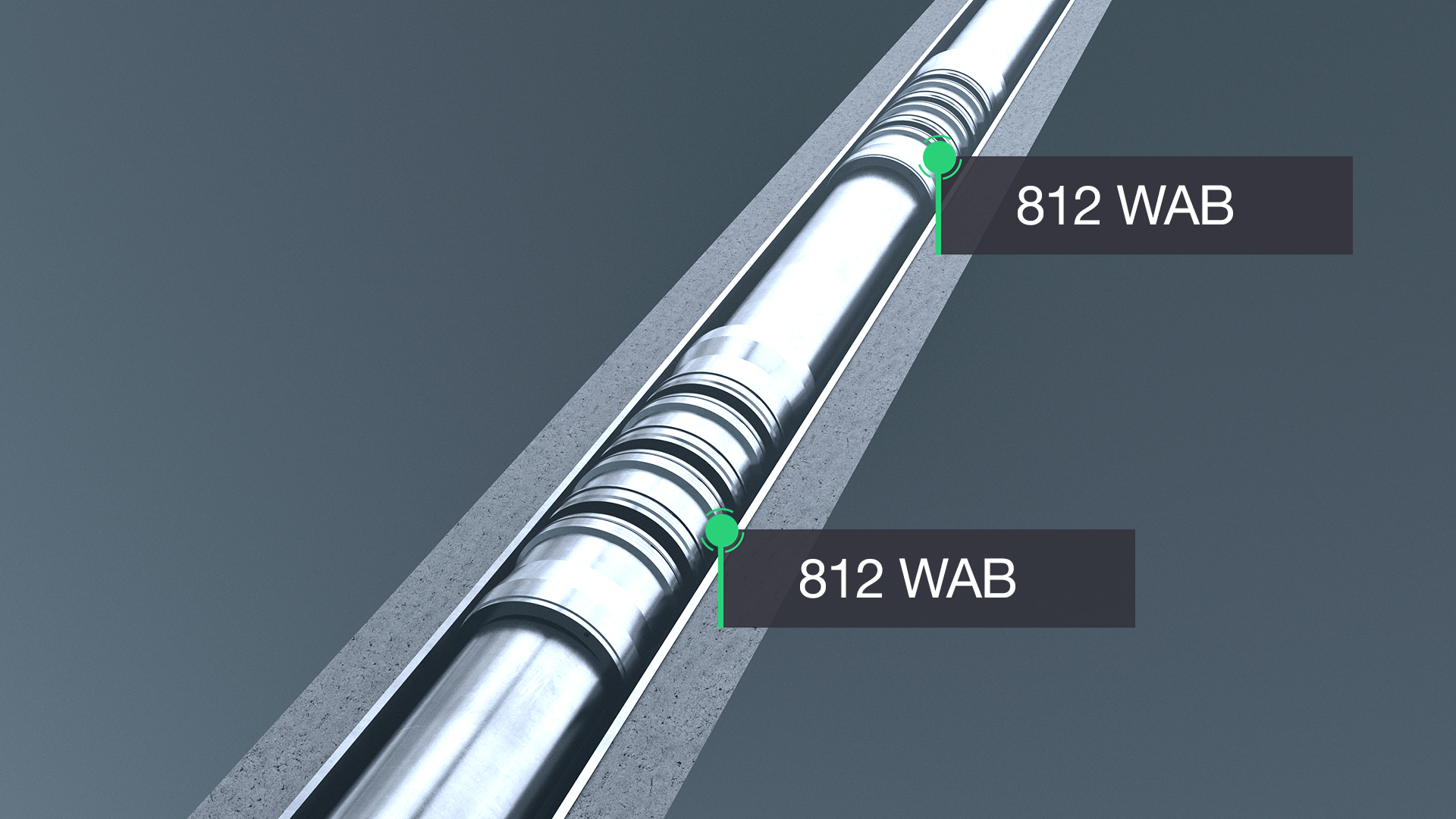

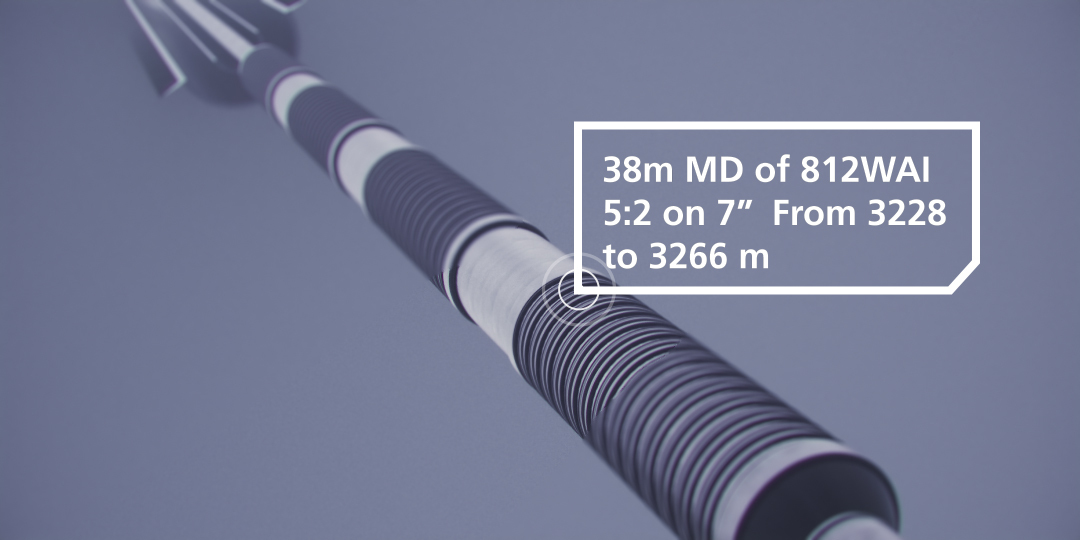

Four 812 WAI joints, each with three 2 m expansion sleeves per joint, were installed on the 7” liner. After installation, a caliper was run to confirm hole condition. This run identified a washed-out section of the 8-1/2” section, so the WAI depth was adjusted accordingly. The WAI sleeves were positioned to straddle the cap rock (claystone). The WAI was then expanded with the formation isolation valve closed with 5,000 psi (345 bars) of differential pressure and held for 10 minutes.

The WAI now provides the primary well barrier across the cap rock, isolating the upper limestone formation. Compared to the original well design, injection capacity significantly increased by installing 5-1/2” screens instead of 4-1/2” screens. The additional section of the 5-1/2” area minimizes delta P loss from the high injection rates and substantially increases the production capacity of the nearby producer.

Achievements

This operation was the very first WAI deployment for Lundin and was also the first such completion performed in the North Sea. The WAIs were installed across the cap rock, and are now providing a life-of-well annular barrier, as per regulatory requirements.

The new well design increases value to the client by allowing a substantially higher injection rate, giving pressure support to the oil producers over the life-of-well, with an 8-1/2” reservoir section as opposed to 6”. The WAI solution reduced the complexity, risk, and hardware needs while saving a calculated 10 days of rig time with associated costs and CO2 emissions, giving return on the WAI investment from day one. Two more high profile water injection wells are already planned for Lundin (Solveig field), and are set to include the same WAI solution from Welltec.