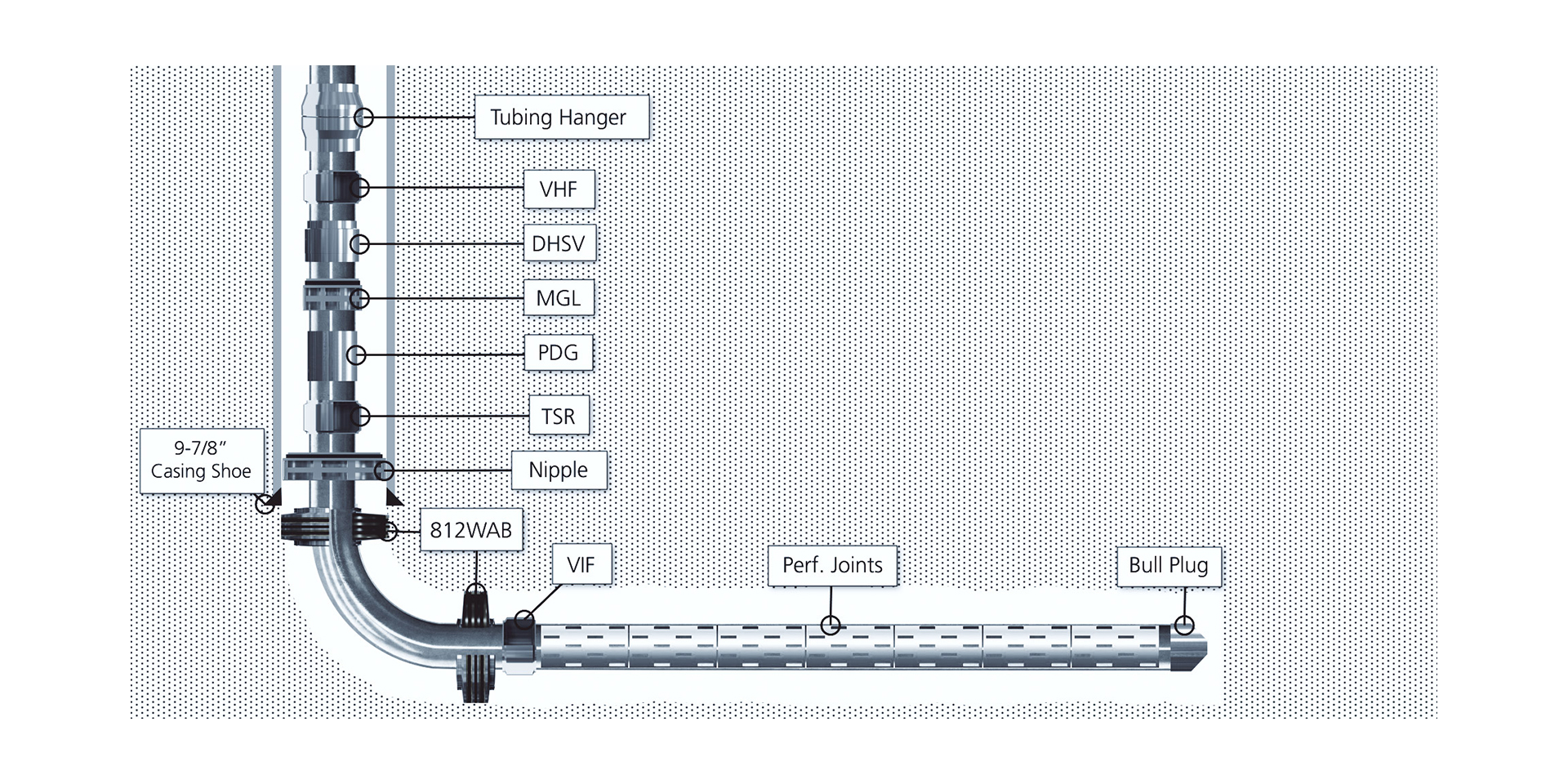

812 WAB® application in pioneering completion system

- Casing shoe 9-7/8”

- Open hole reservoir section 8-1/2”

Background

One of Welltec’s clients had developed a pioneering completion delivery system, consisting of only three phases to drill a well, followed by a signature maneuver to install the completion in one operation.

The key drivers and benefits related to this method are savings of approximately 50% on time and cost, as well as the prospect of then applying the technique throughout a planned post-salt development in a deepwater environment.

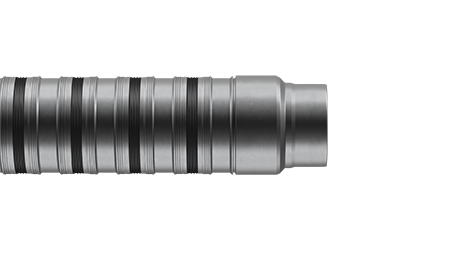

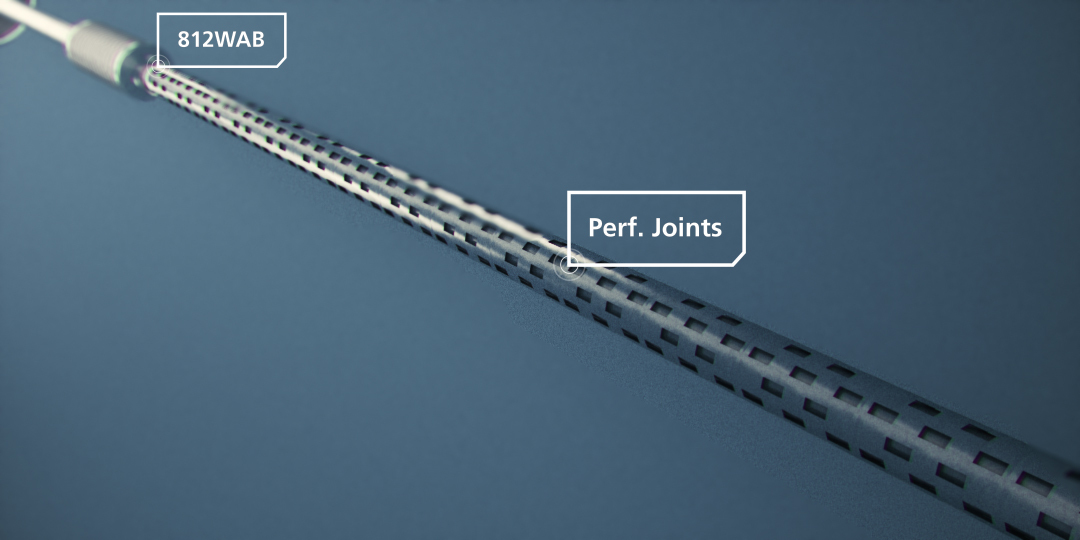

As a necessity for the system, the client required a packer that could provide open hole isolation across the 8 ½” reservoir section and compensate for the presence of faults and unconsolidated sandstone. The packer could then further facilitate a successful job by eliminating an entire stage in drilling, casing and cementing.

Welltec® provided two packers, each in the form of an 812 Welltec Annular Barrier (WAB®) to achieve the required open hole zonal isolation.

Operations

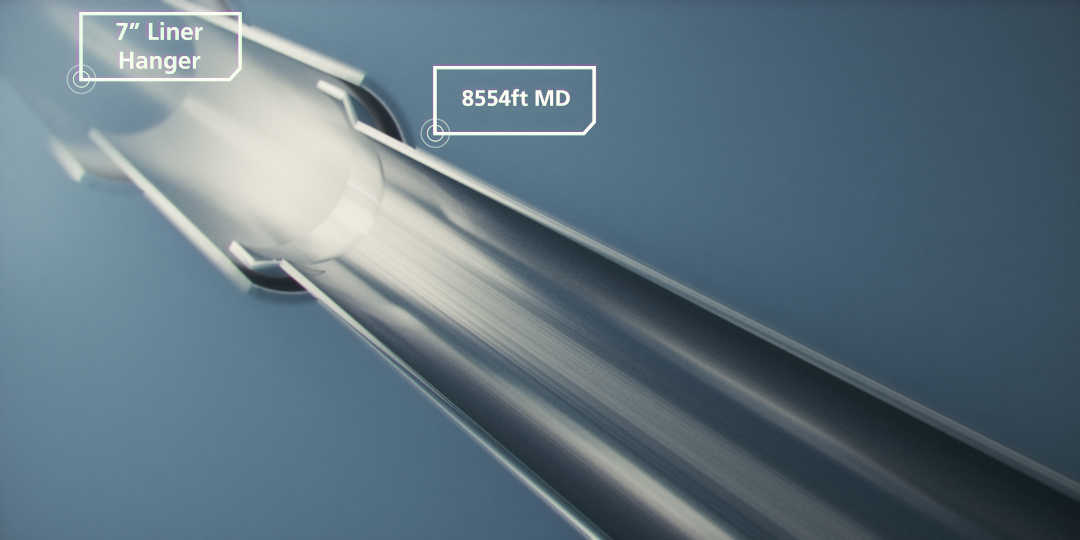

The client’s system design included a pre-perforated lower completion that incorporated a Formation Isolation Valve (FIV) directly above the pre-perforated liner.

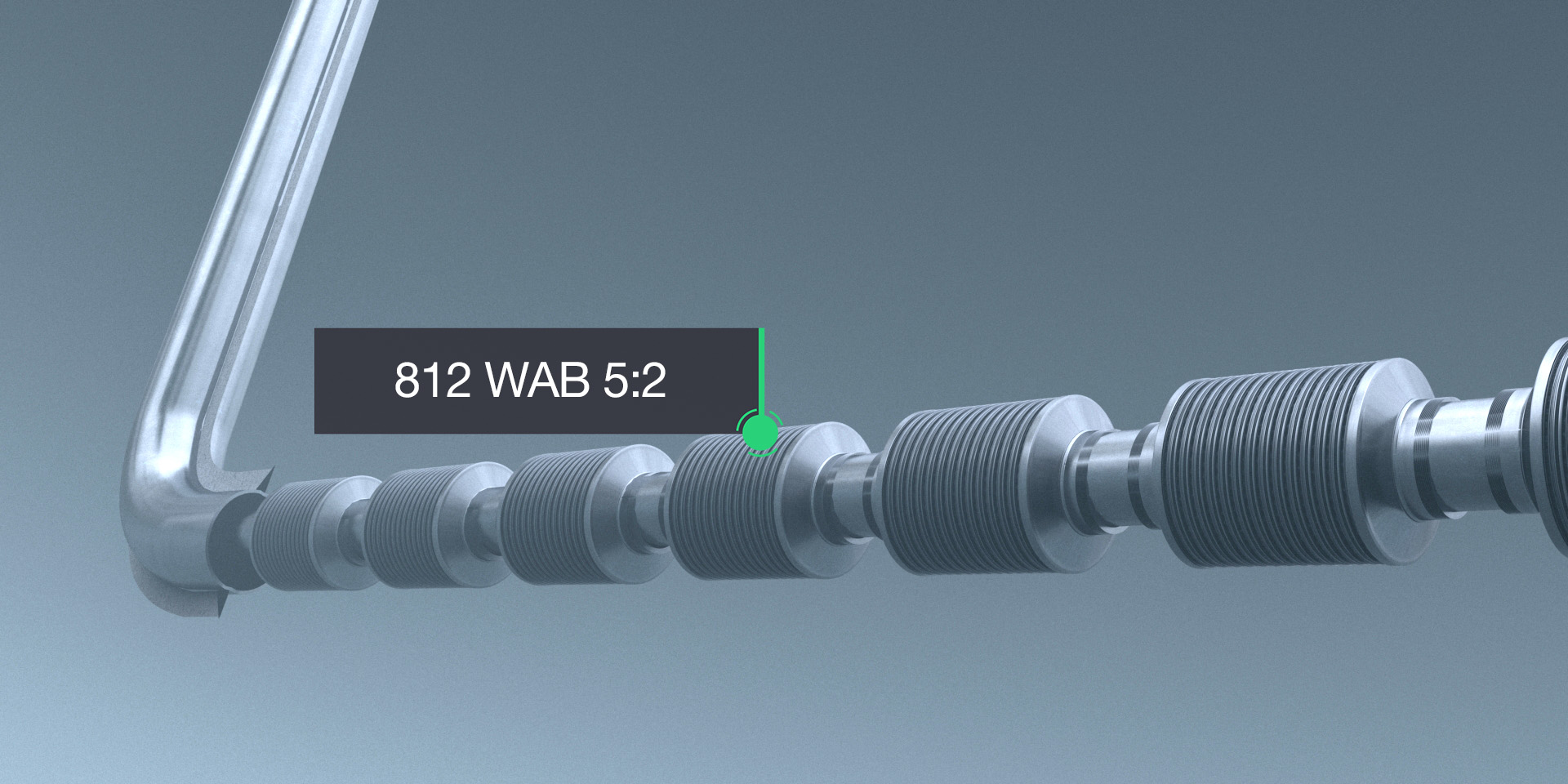

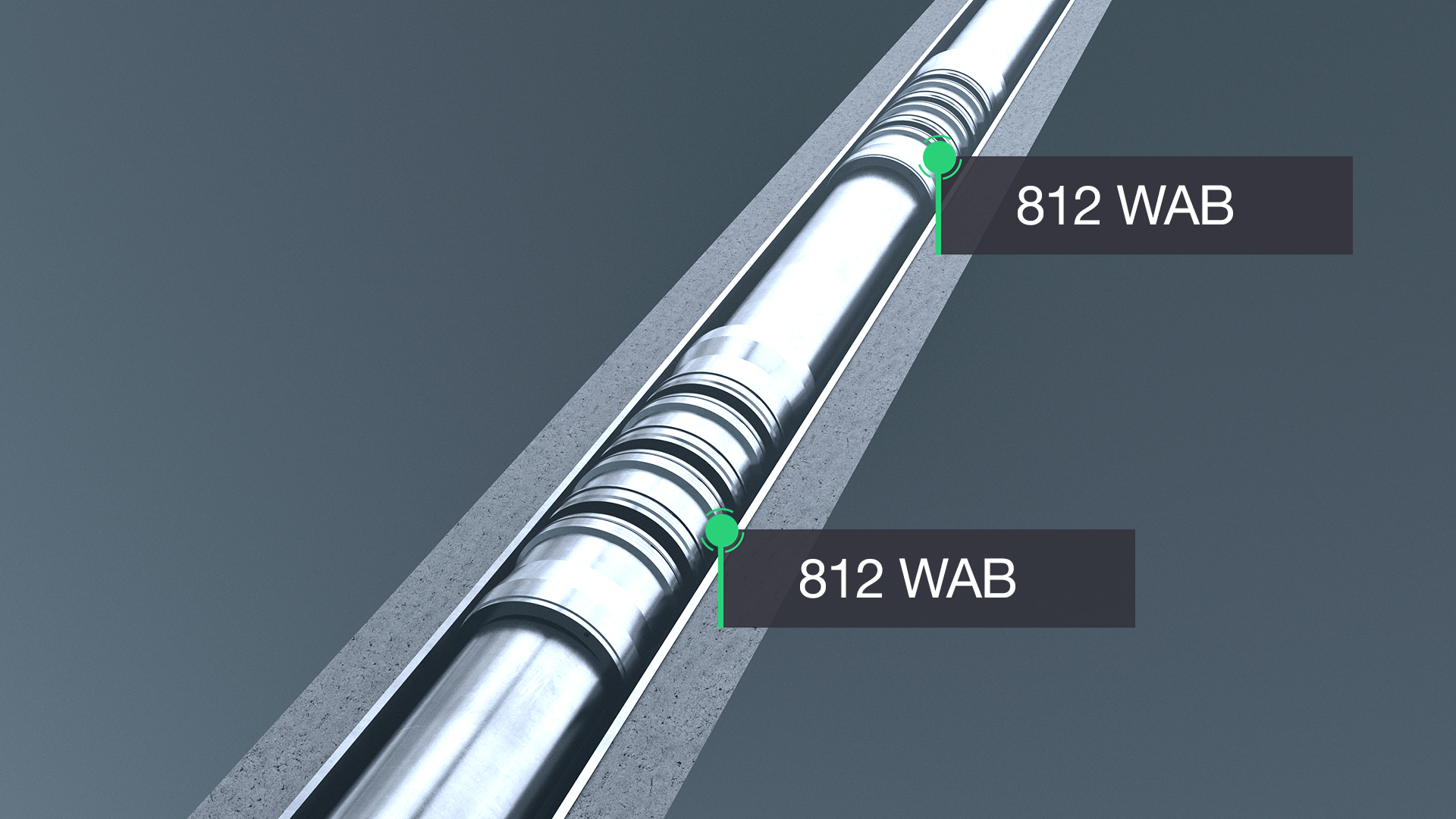

The upper WAB was positioned at a point below the 9 7/8” shoe to isolate a sandstone reservoir that the client had no requirement to produce from and therefore needed life-of-well isolation. The lower of the two WABs was positioned at a point within the reservoir that when coupled with the upper WAB provided isolation of a fault directly above the reservoir section. Furthermore, the 812 WAB expands to a maximum of 10” and therefore mitigates for a worst-case scenario washout within the reservoir section.

Once the FIV was closed, this allowed the application of surface pressure to simultaneously set both 812 WABs within the 8 ½” reservoir section to provide zonal isolation.

Achievements

The completion of the well was concluded in 44 days, resulting in $30M savings on projected conventional well completion costs, made possible by the client’s delivery system.

Outwith the primary solution provision of fault and sandstone isolation, the WAB for zonal isolation enabled efficiencies by removing the need for certain design elements in the well, in effect preventing additional operations which would incurr costs.

In the structural sense, the WAB enabled the exclusion of one complete hole section, and the extra cementing across the section. This subsequently avoided a clean-out run, changing of well fluid, wire-line logging for evaluation of the cement, and contingency liner tie-back.

During installation, despite the client experiencing operational issues with the tool string – and setting the WABs 70 meters above target depth – the sandstone reservoir was properly isolated by the upper WAB to deliver reduced costs, as well as prevention of unwanted production. In the long term, the completion design will also deliver optimized plug and abandonment.

Well schematics