Welltec® Light Packer for cement assurance and eliminating SCP

Background

In the oil and gas sector, Sustained Casing Pressure (SCP) is a persistent issue, directly linked to compromised well integrity and associated safety and environmental risks, including unintentional methane emissions.

A CEA (Central and East Asia) client faced SCP challenges due to a high-pressure target formation causing microannulus issues between the B-annulus and production casing, giving rise to pressure building up in the well and posing a threat in terms of unwanted release of gas into the atmosphere.

Conventional cementing methods were inadequate to remedy the issue and so the Welltec® Light Packer (WLP) was identified as a technical solution to not only ensure well integrity, but also to prevent harmful emissions.

Operation

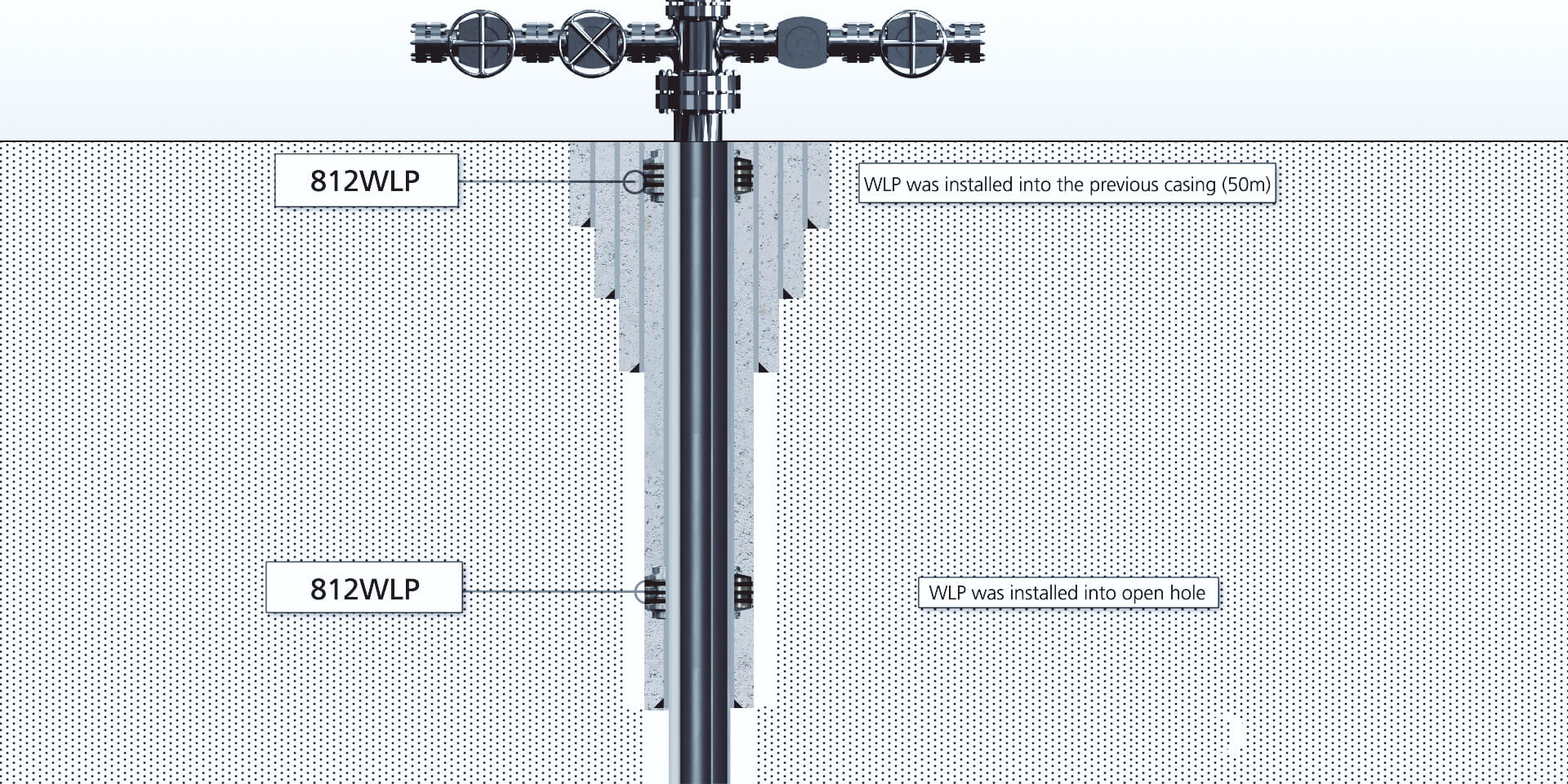

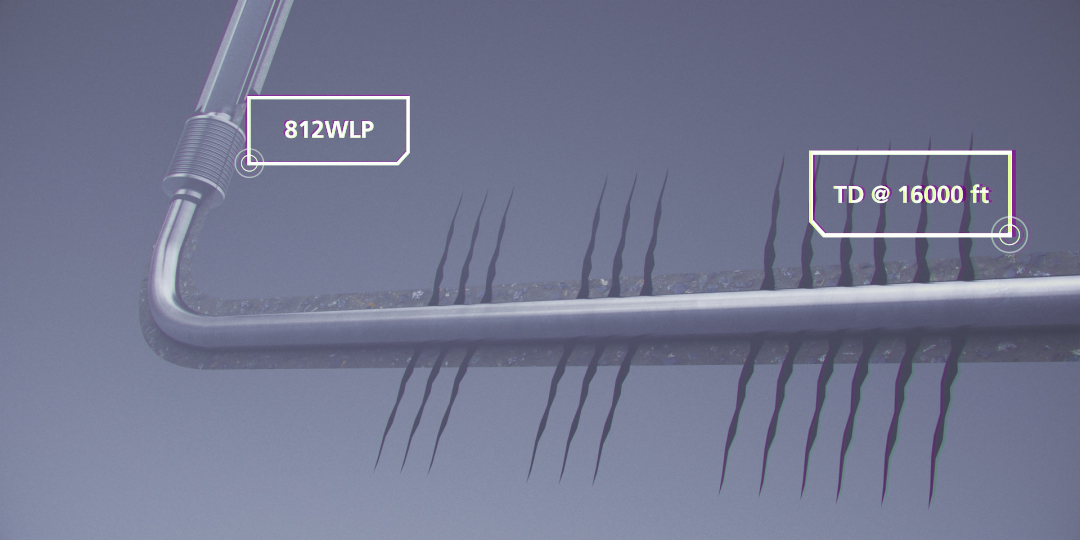

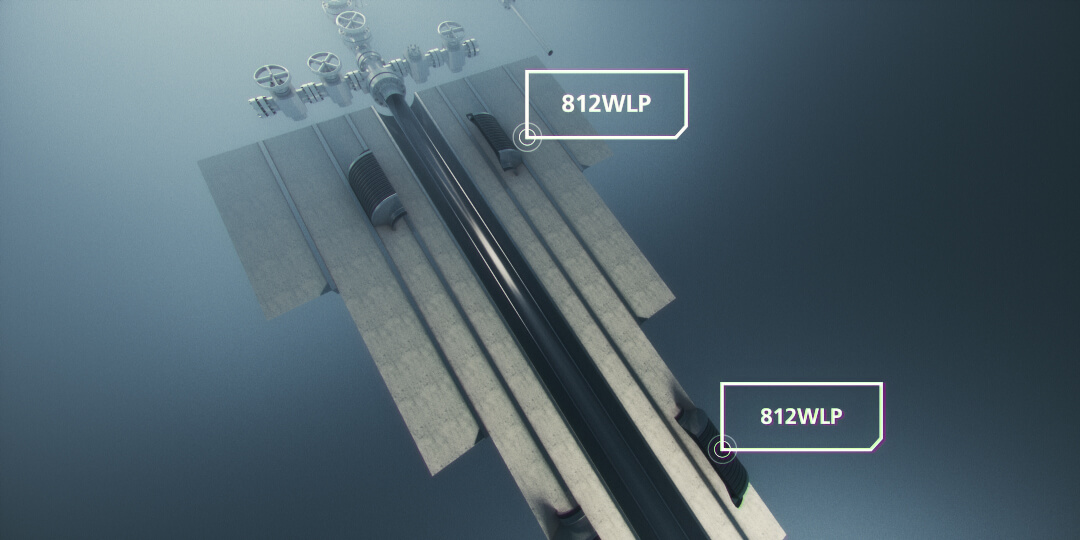

In collaboration with the client, Welltec proposed an SCP prevention agenda. This led to the development of the 8.5” Light Packer (812WLP), strategically designed to eliminate SCP and enhance operational efficiency.

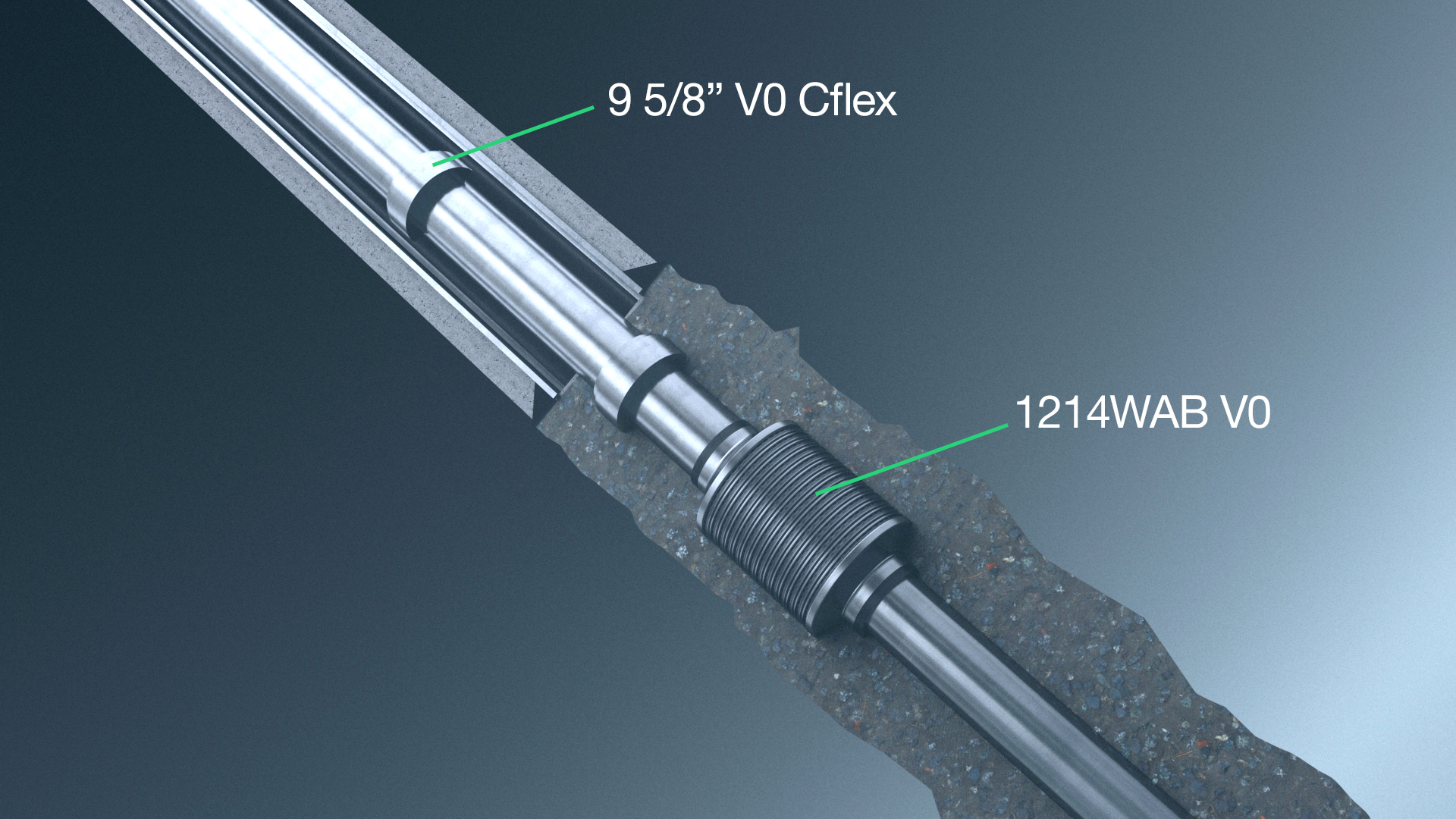

Installed as part of a 7” production casing, the 812WLP 10k featured a compensation system capable of withstanding up to 10,000 psi well pressure, exceeding the requirements of the high-pressure target formation. Being fully rotatable, this allowed the completion string to navigate obstacles without compromising packer integrity.

The WLP was run to a vertical depth 600 m below the permafrost zone. Safety measures included an onset valve to prevent unintentional setting during high-pressure activities, and a sheer-pin valve for post-WLP setting to ensure well integrity.

Achievements

The operational outcomes were substantial. SCP was completely eliminated from the well, establishing the 812WLP as a reliable completion solution. Every well equipped with a WLP has experienced zero SCP and zero emissions, attesting to its effectiveness.

From a technical standpoint, the elimination of SCP translated to a reduction in the need for future interventions, eliminating associated logistical and operational challenges. This operation not only ensured well integrity but also provided significant environmental safeguards by preventing the release of harmful greenhouse gases such as methane.

Well schematics