812WAB® abandonment plug isolates total losses

- Well type Oil producer

- Reservoir type Sand

- Short term delivery requirement facilitated by Welltec's manufacturing capability in Denmark

- Incorporation of wab oh isolation plug resulted in Approx. USD 2 million in cost savings per well.

- Award in India Breakthrough award & deployment for major IOC

- Location India

Background

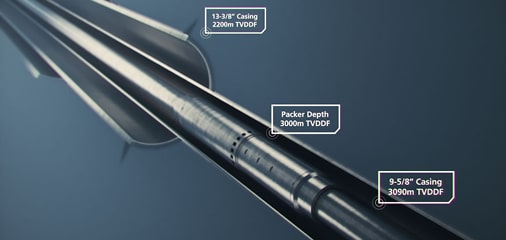

A NOC in India required a solution to provide permanent isolation of a depleted reservoir (if encountered) during the drilling phase on a 3 x well, side track and subsequent single zone gravel pack completion campaign. The inability to isolate the depleted zone would result in substantial increase in risk, time and cost during the gravel pack operation.

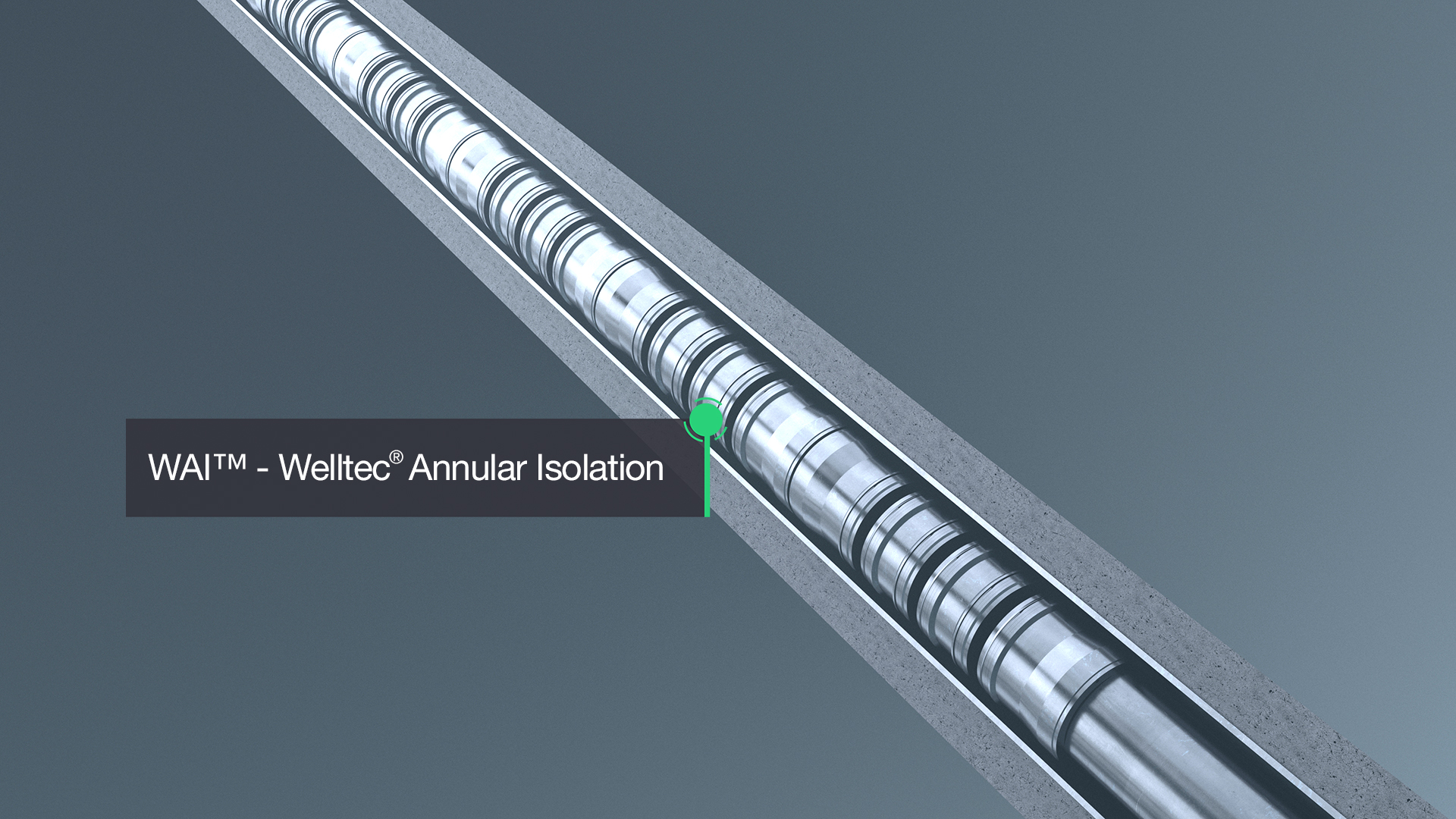

Swell type packers were not considered a viable solution due to ∆p requirements and the associated down time for swell along with the poor life of well characteristics of the swell type material. Furthermore, ECP type solutions were not considered as they require to be set with cement to safeguard against the thermal fluctuations within the application.

Solution

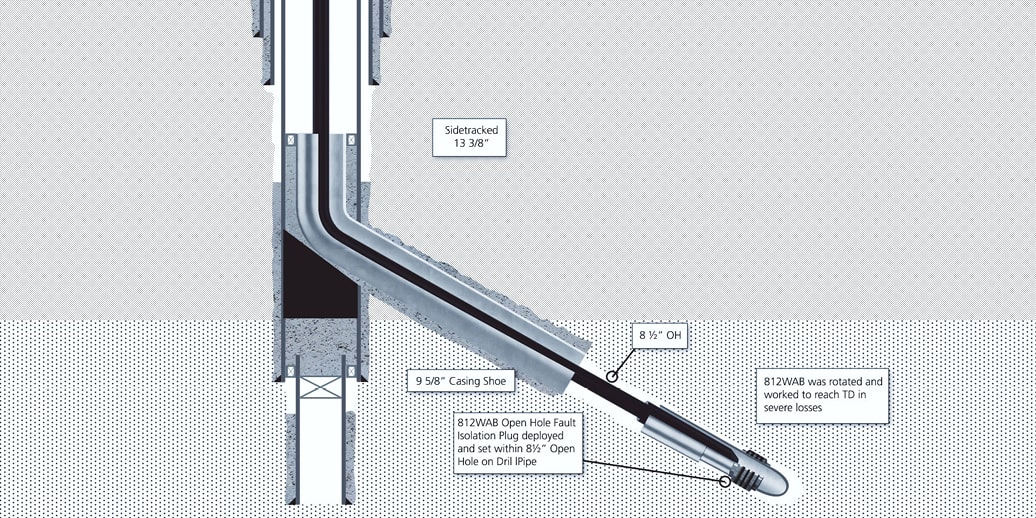

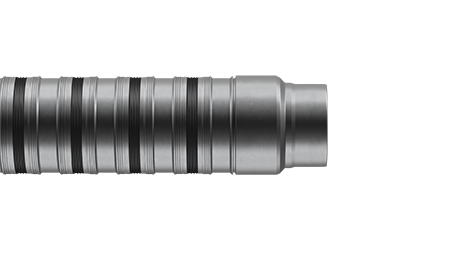

The Welltec Annular Barrier® (WAB) was selected and utilized as an open hole fault isolation plug, allowing the depleted reservoir to be permanently isolated enabling a routine gravel pack lower completion to be deployed. The system enables rotation and circulation of the WAB during deployment.

A solution was available for both the primary 8 ½” hole section as well as the 6” contingency hole. Across all wells, the reservoir section drilled to 8 1/2" open hole size, and the 812WAB was deployed, on drill pipe, as a life of well solution to the total losses and was applied as follows:-drill the 8 1/2" open hole. Once fault is encountered – stop drilling and POOH drill bit.

RIH with 812WAB on toe valve + float shoe – ran on drill-pipe coupled to a hydraulic release running tool. TD – p/up to neutral and apply hydraulic pressure down DP to set WAB above / across the fault drop ball and then apply release pressure liner running tool.

POOH

The set 812WAB then became the sump of the well, permanently isolating the fault and facilitating the completion of a GP lower completion above.

Achievement

Collaboration between client & Welltec® resulted in HP isolation in the most extreme environment.

812WAB fault isolation solution allowed client to realize 50% CAPEX reductions, when compared with previous LCM mitigation methods, along with risk reduction for the subsequent gravel pack completion, resulting in complete pack placement.

Isolation of total losses allowed for deployment of single zone gravel pack completion.

WAB open hole isolation plug, enables CAPEX effective and reduced risk gravel pack completion via isolation of total losses.